Soft Robotics

Soft robotics is a subfield of robotics that focuses on the design, fabrication, and control of robots made from flexible, deformable materials such as silicone, rubber, or other polymers. These robots are inspired by the movements and adaptability of living organisms, such as octopuses, worms, and human muscles. Unlike traditional rigid robots, soft robots excel in interacting safely with humans and adapting to unstructured environments.

Key Characteristics of Soft Robotics

1. Flexibility:

- Soft robots are highly pliable, allowing them to bend, stretch, and compress without damage.

2. Adaptability:

- They can conform to complex surfaces, navigate confined spaces, and perform tasks in unpredictable environments.

3. Safety:

- Their soft materials make them ideal for applications where safety is critical, such as healthcare or human-robot interaction.

4. Bioinspiration:

- Many designs mimic biological systems, using nature as a blueprint for efficient and versatile movement.

Core Components

1. Soft Actuators:

- These are the "muscles" of soft robots, typically powered by air (pneumatics), liquids (hydraulics), or stimuli-responsive materials (e.g., shape-memory polymers).

2. Sensors:

- Soft sensors made from flexible materials detect touch, pressure, temperature, or strain, enabling the robot to respond to its environment.

3. Materials:

- Elastomers, hydrogels, and biomaterials are commonly used for their flexibility and durability.

Applications of Soft Robotics

1. Healthcare:

- Surgical Tools: Soft robots can delicately navigate internal organs during minimally invasive surgeries.

- Rehabilitation Devices: Assistive robots for physical therapy or prosthetics mimic natural human movement.

2. Wearables:

- Soft exoskeletons enhance mobility for people with disabilities or improve physical performance.

3. Agriculture:

- Robots gently handle delicate produce like fruits and flowers without damaging them.

4. Search and Rescue:

- Soft robots can squeeze through rubble or narrow spaces to locate survivors in disaster areas.

5. Exploration:

- Their ability to adapt to irregular terrains makes them ideal for underwater or extraterrestrial exploration.

6. Consumer Products:

- Applications include soft robotic toys or devices that interact more intuitively with users.

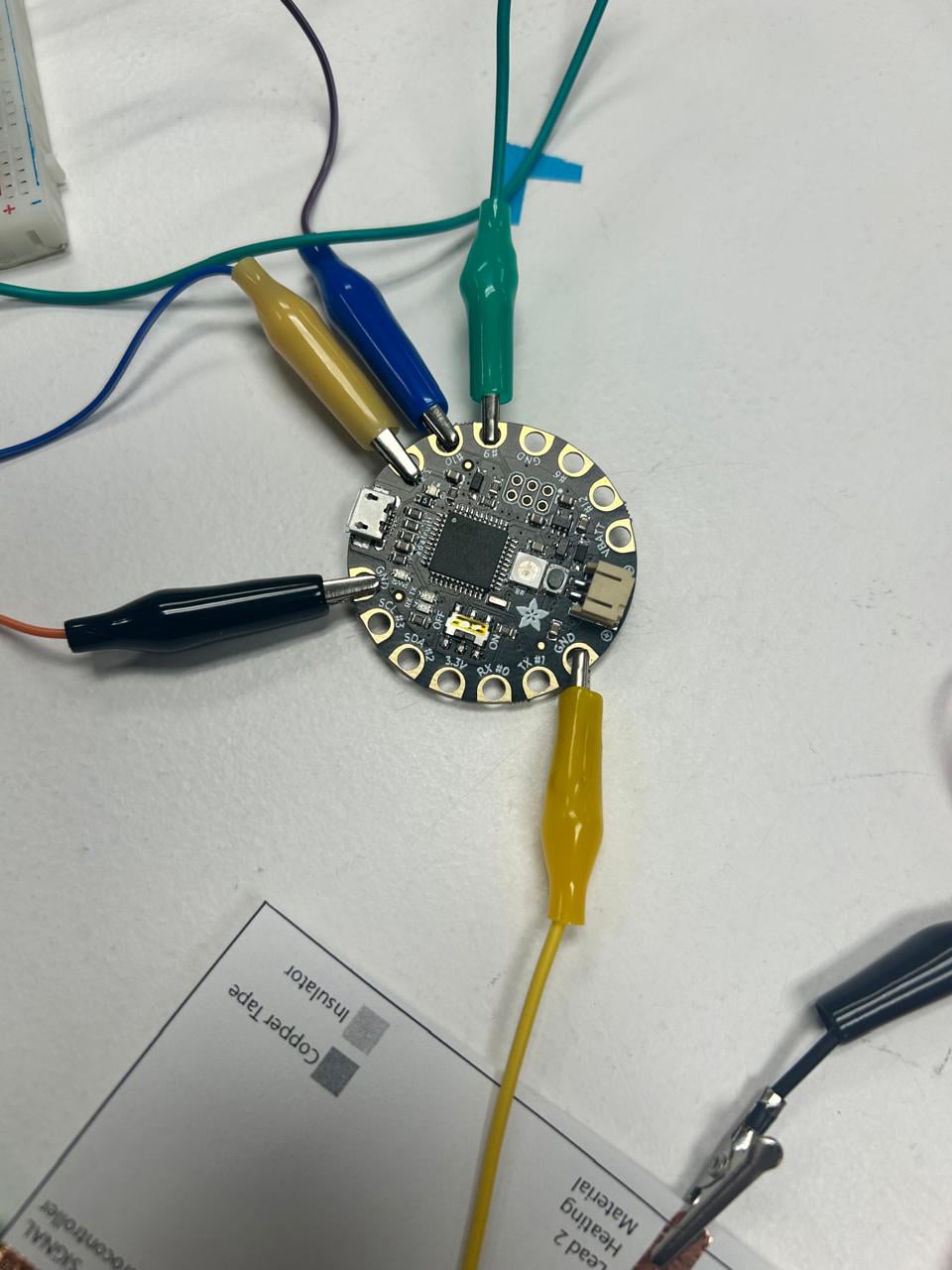

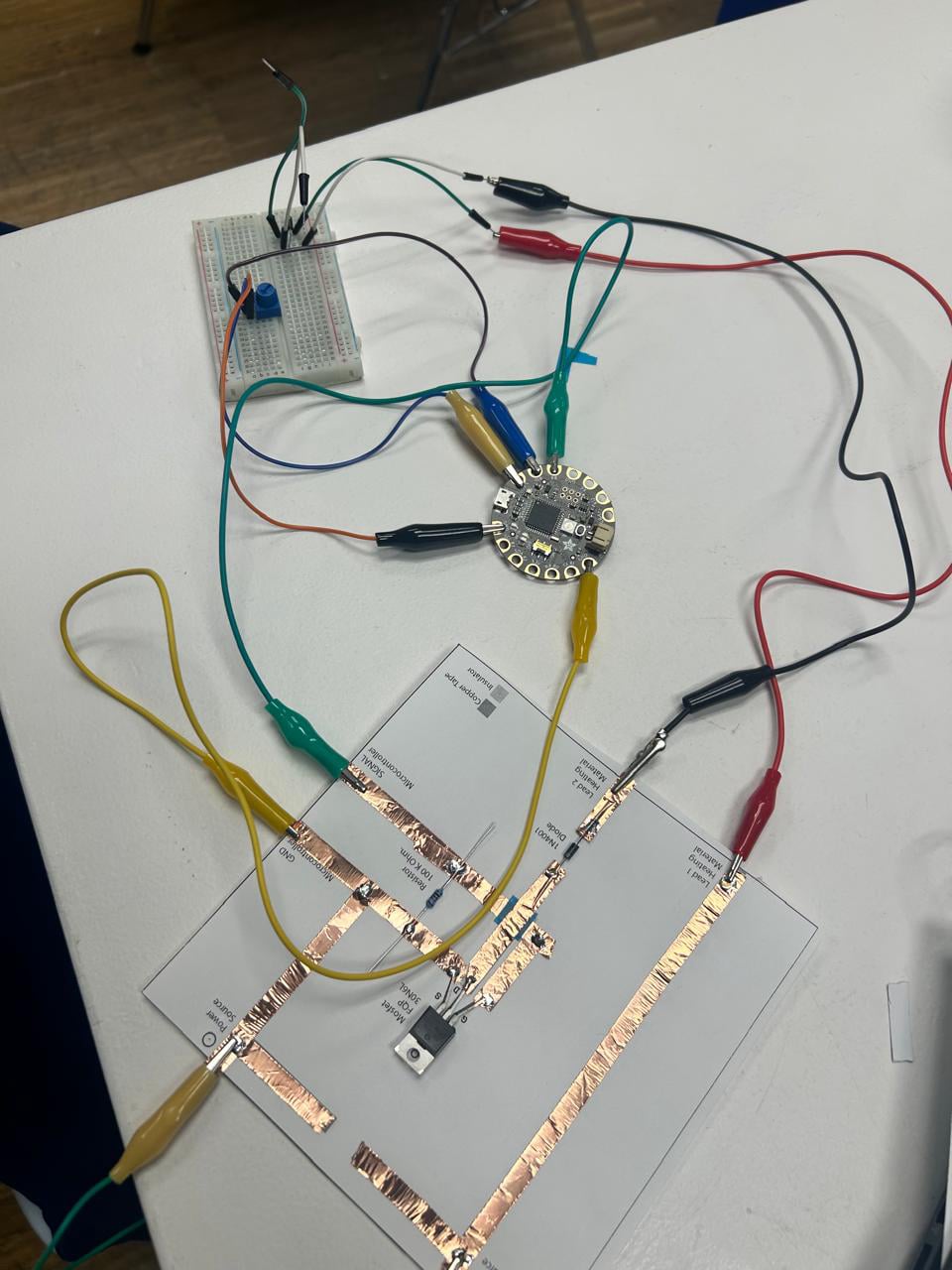

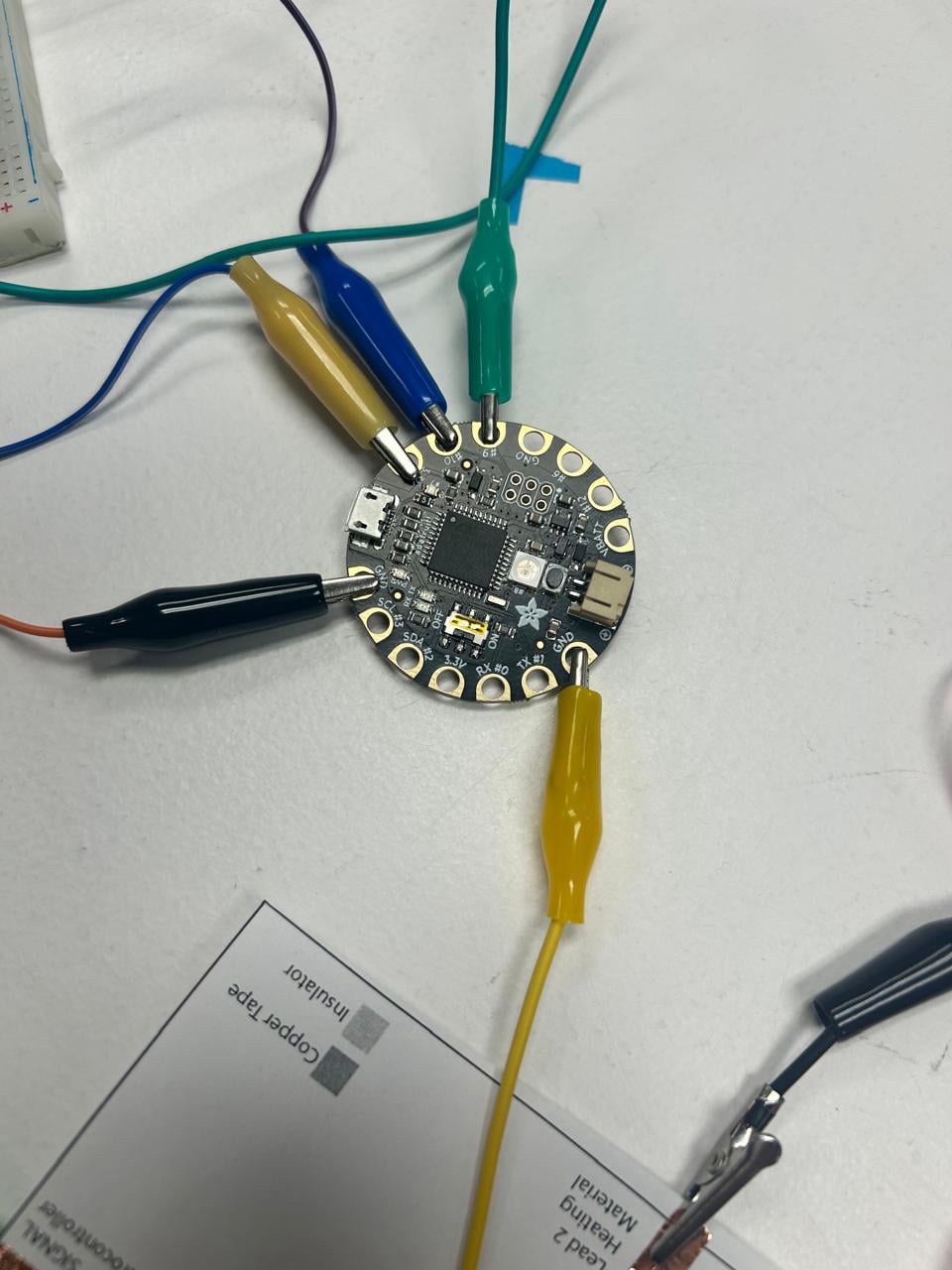

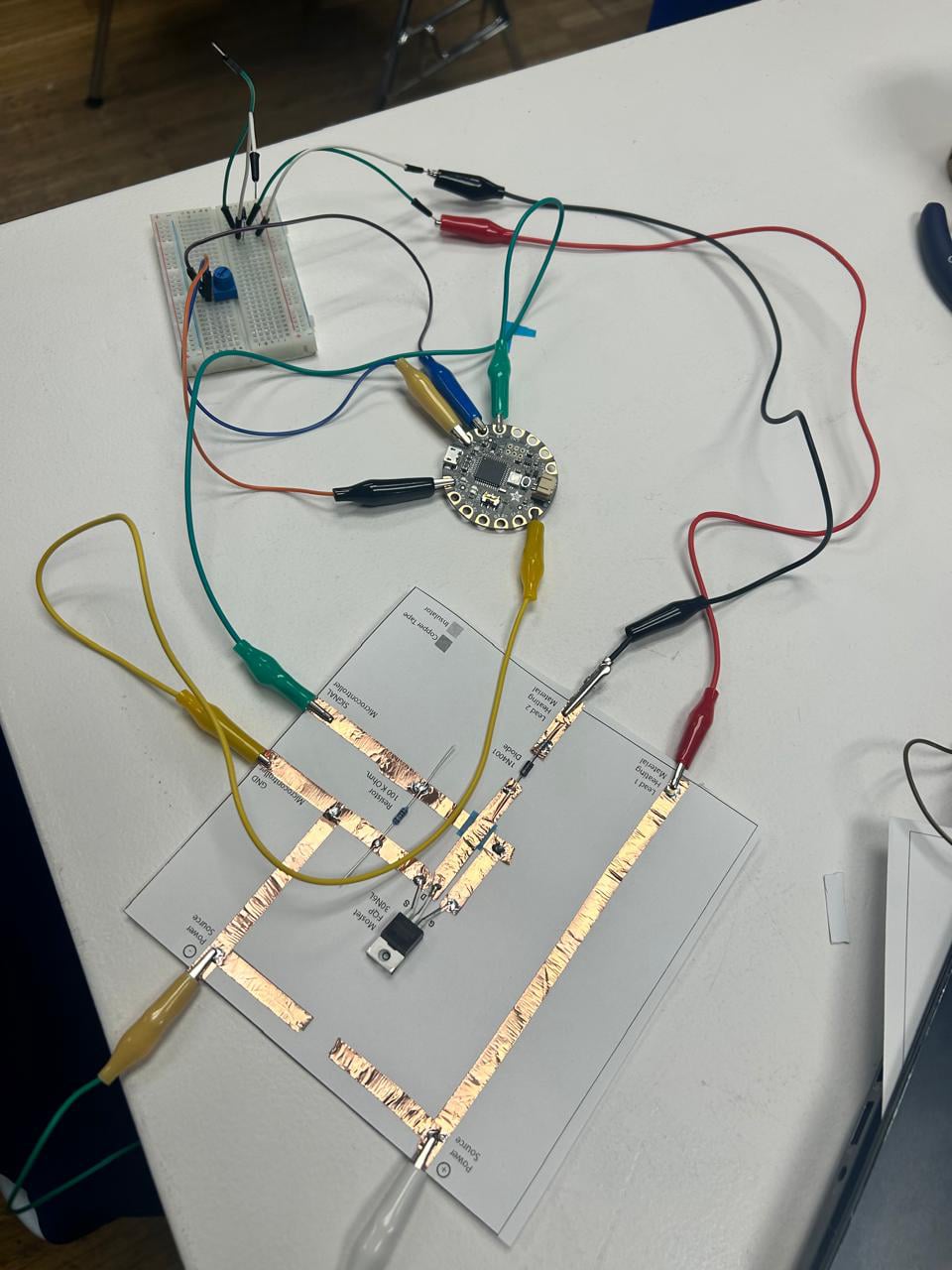

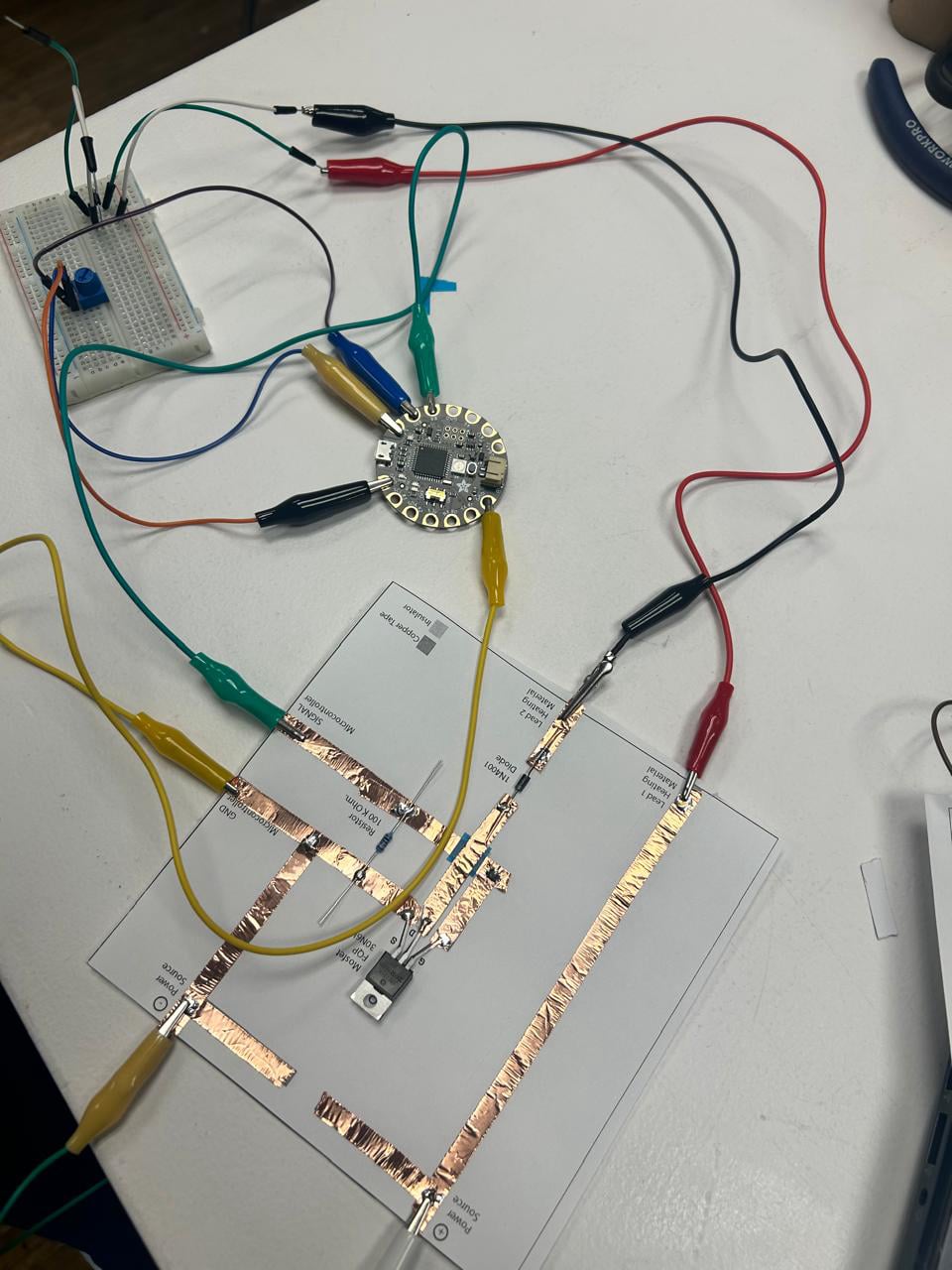

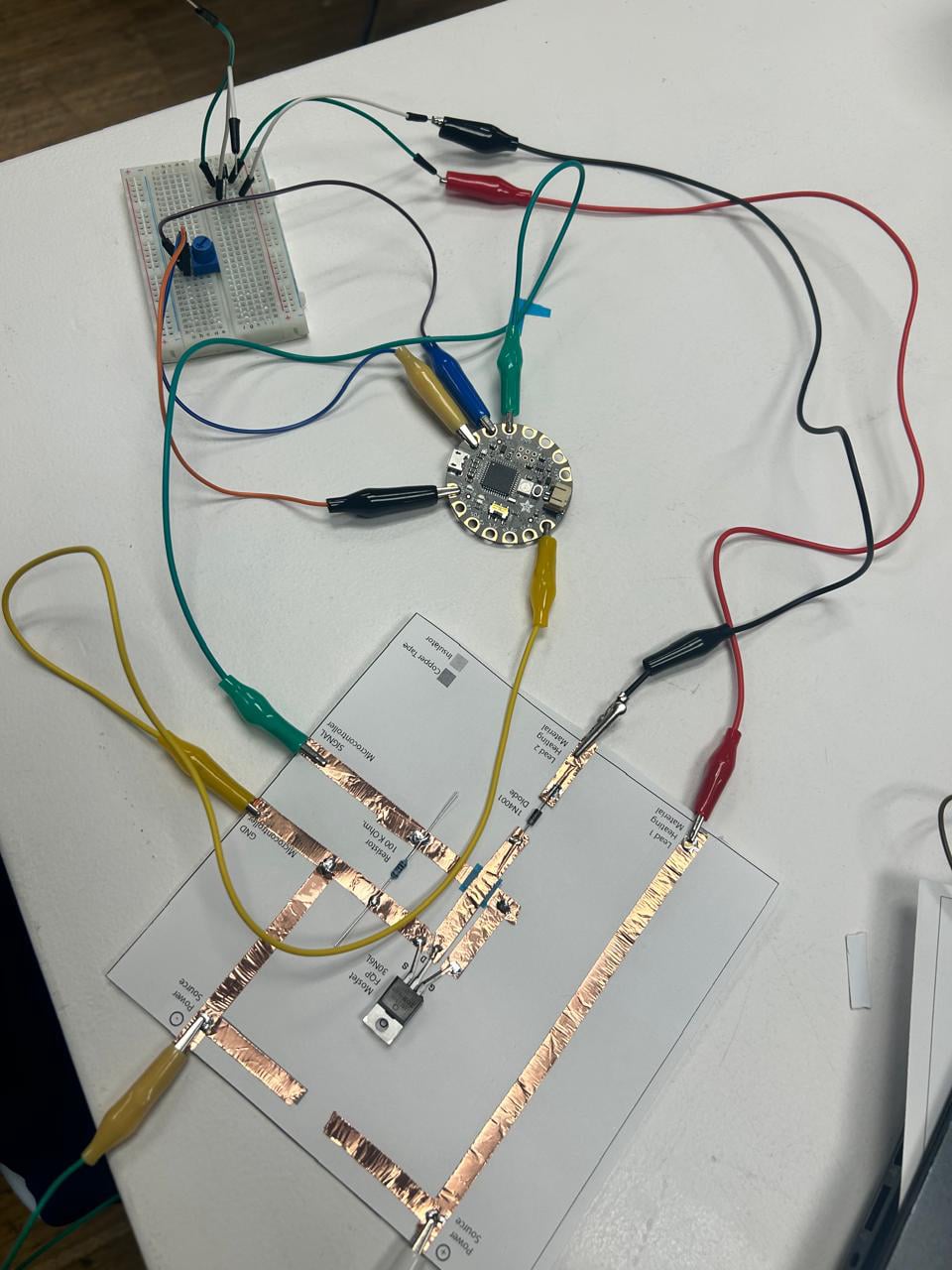

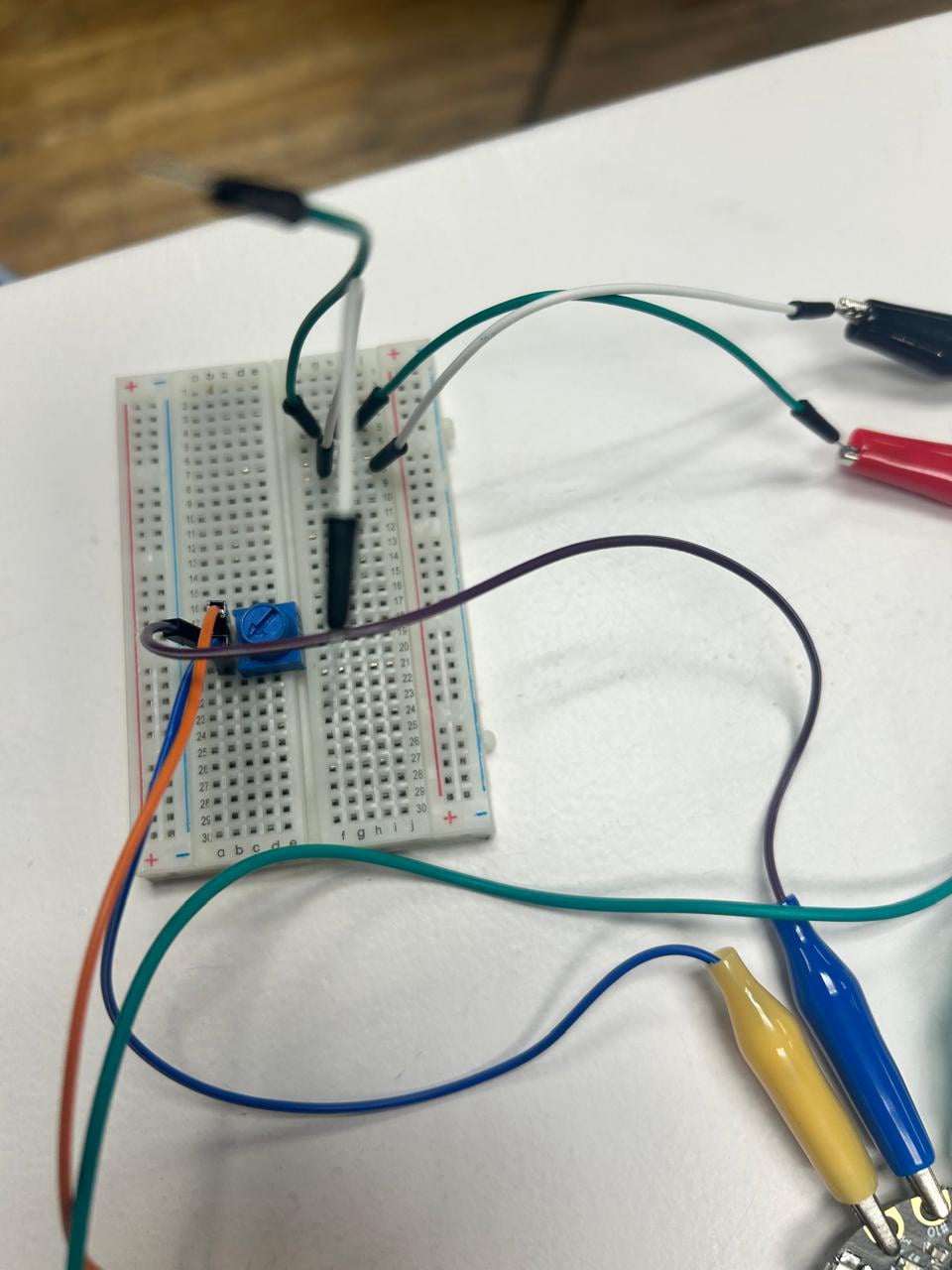

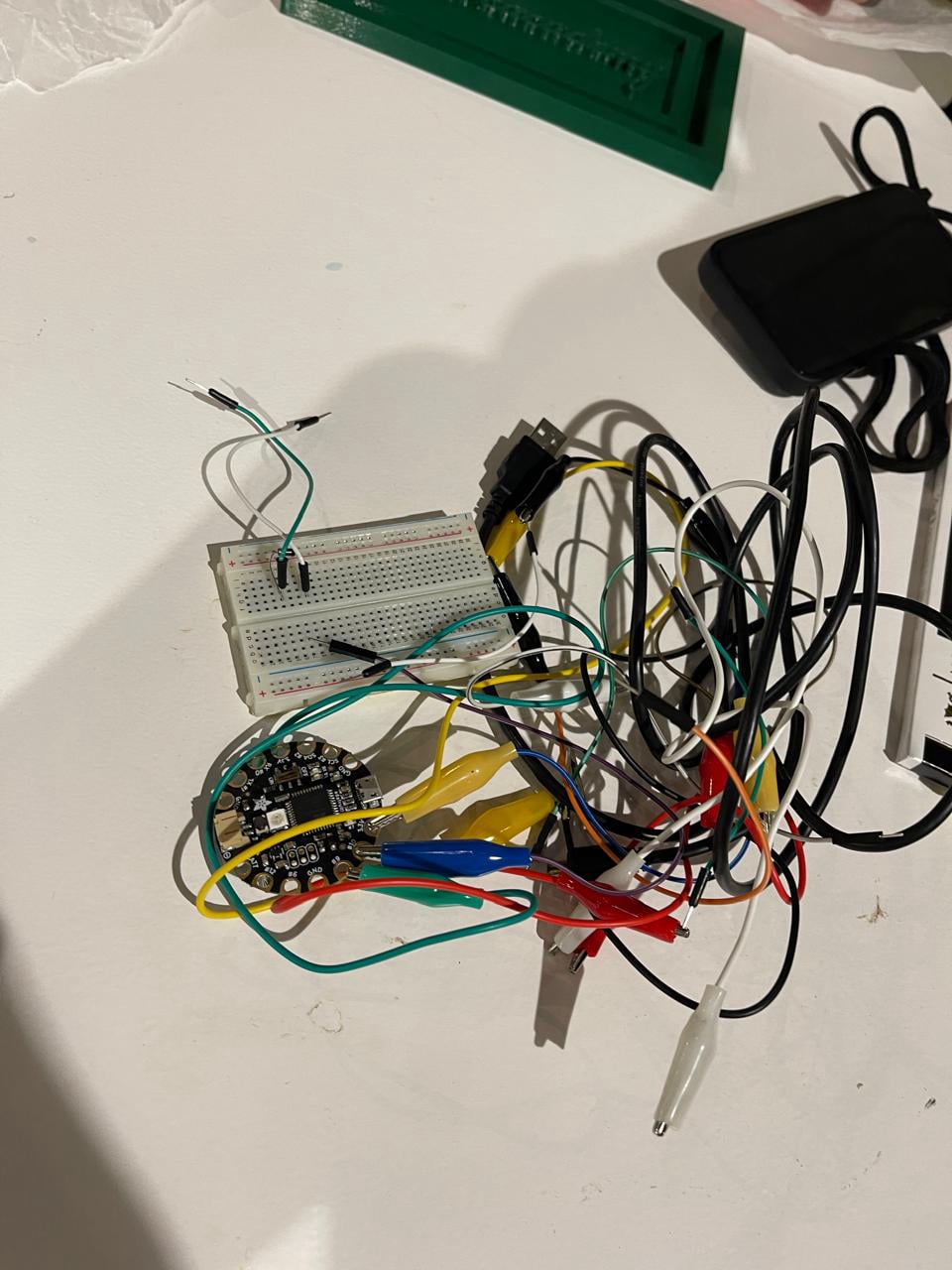

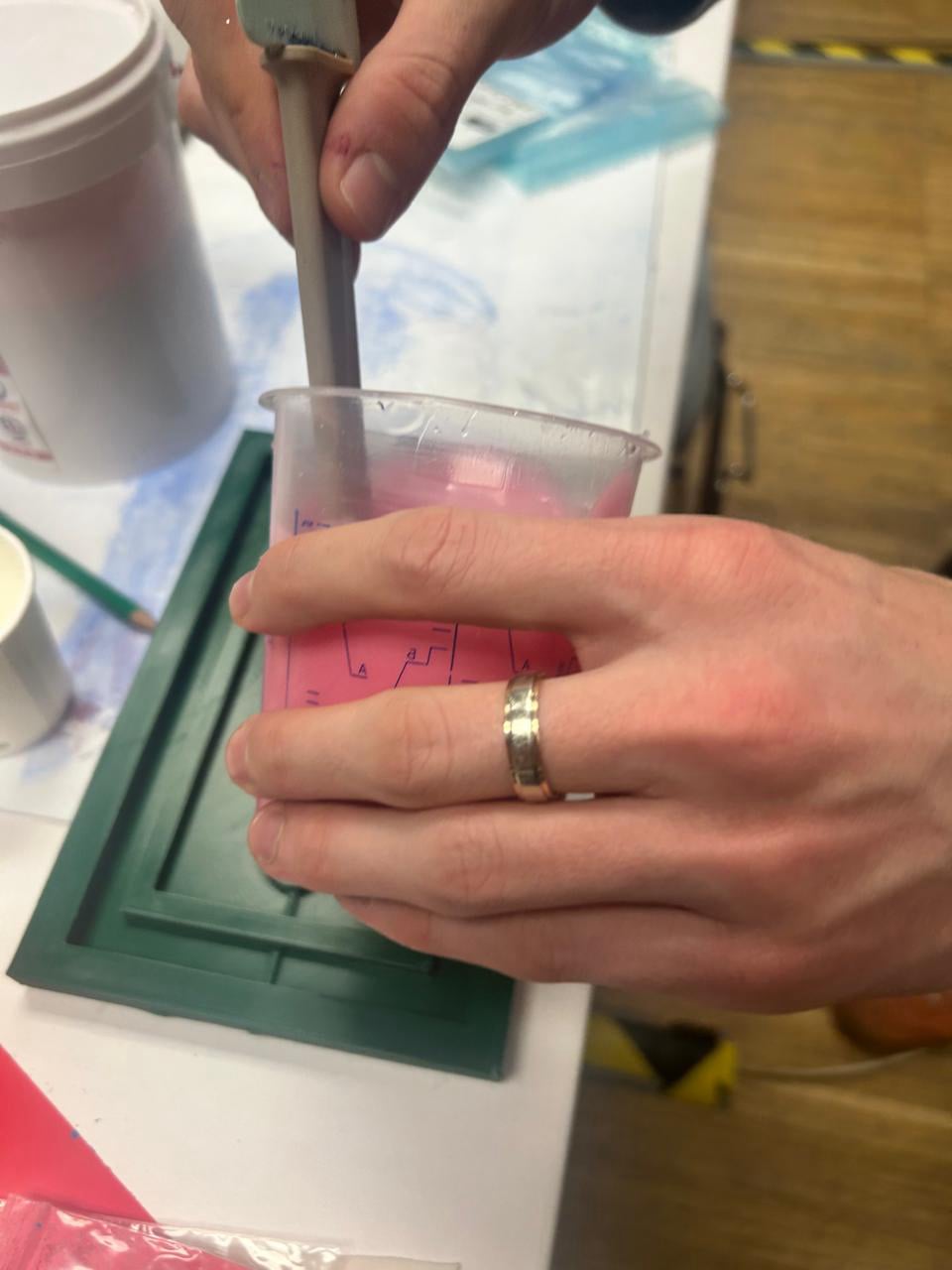

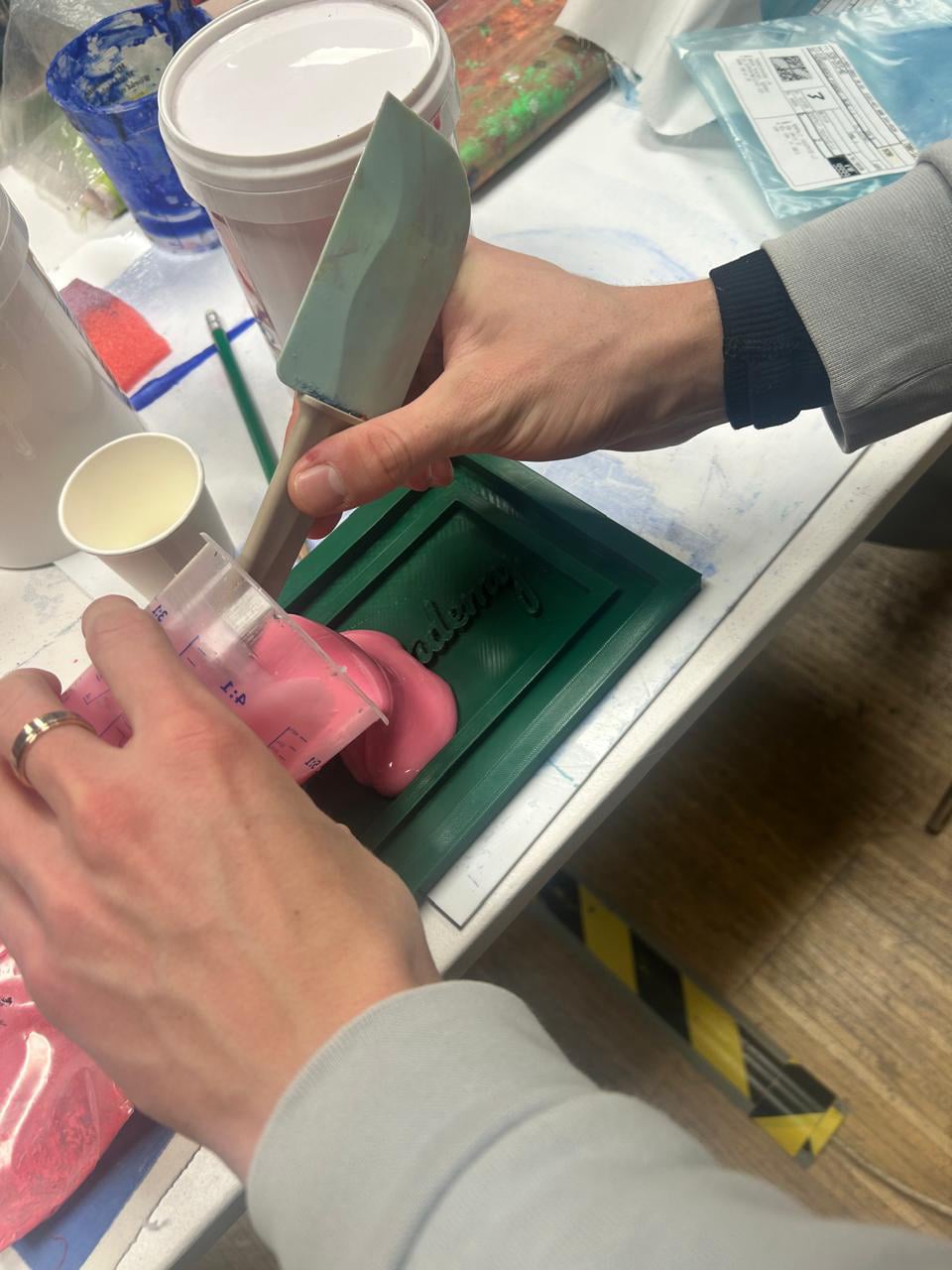

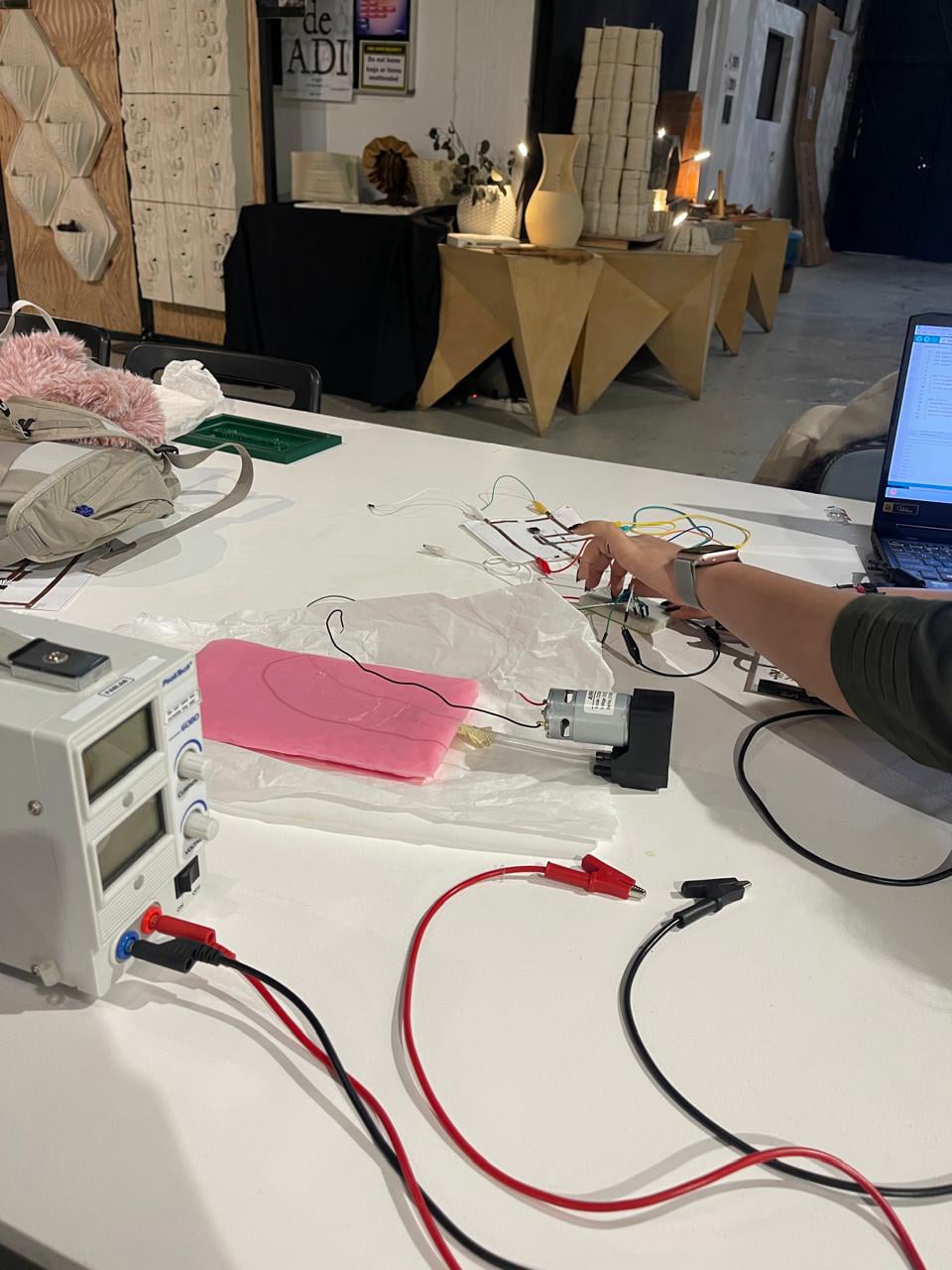

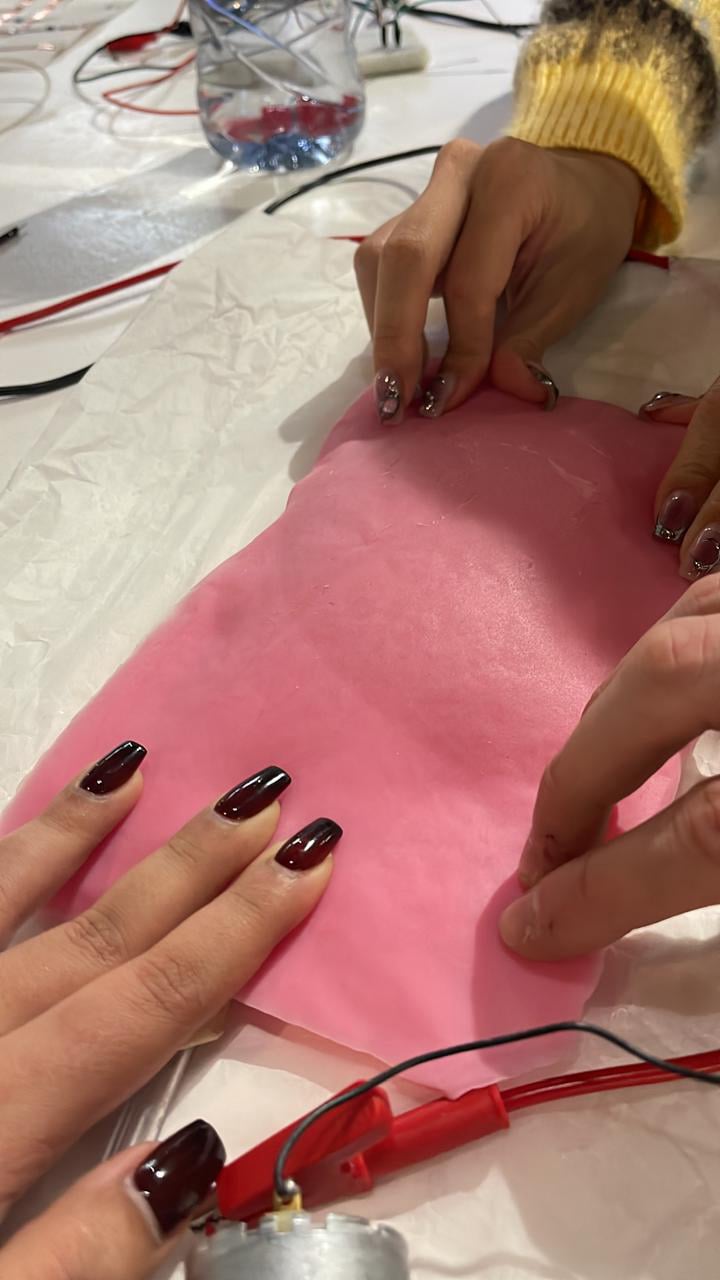

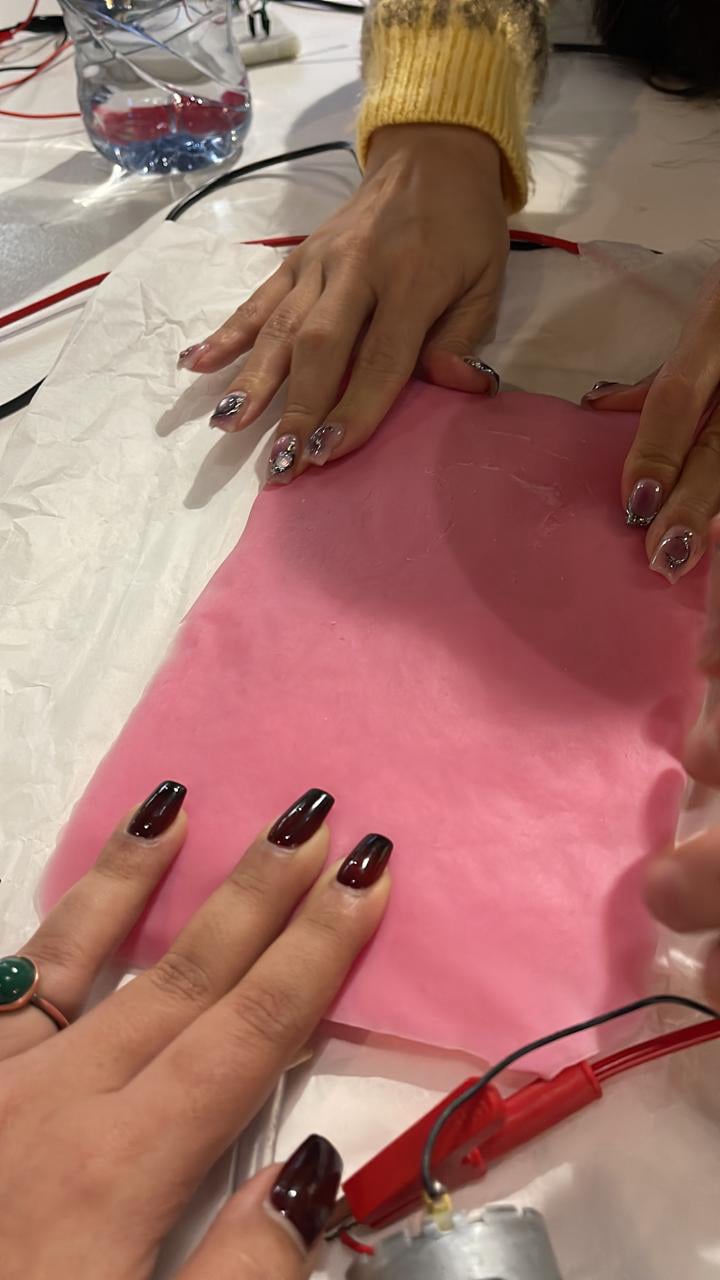

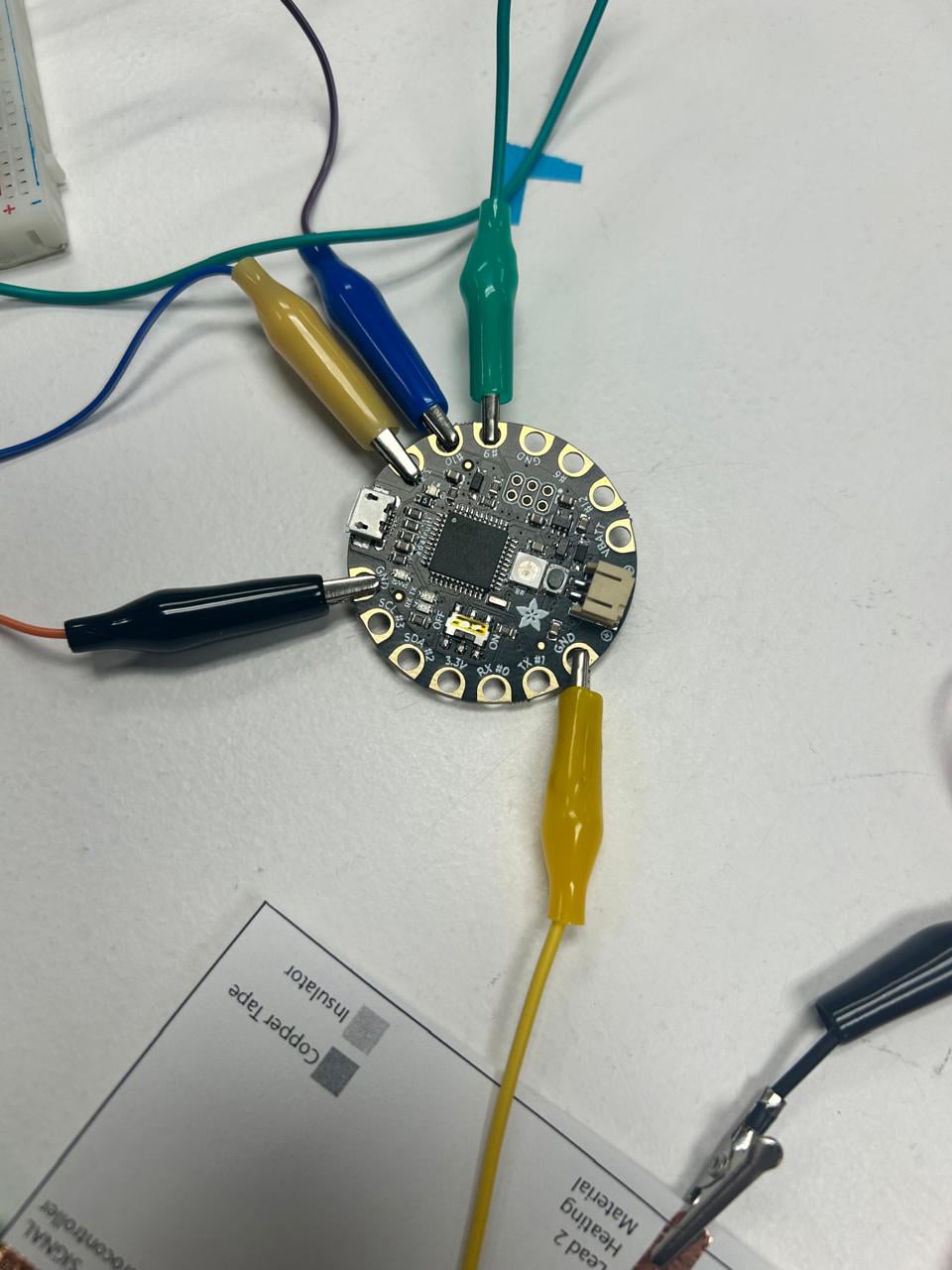

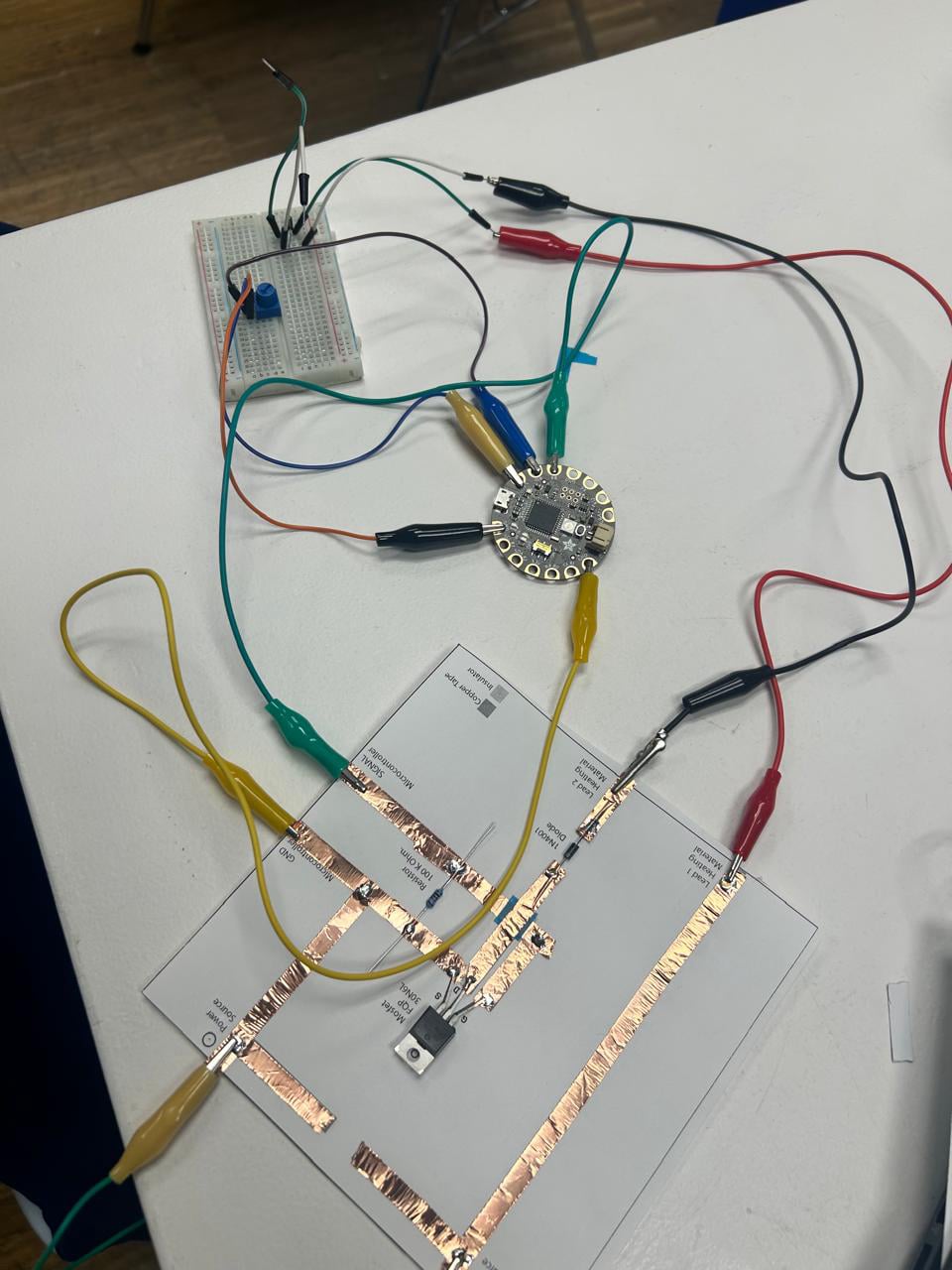

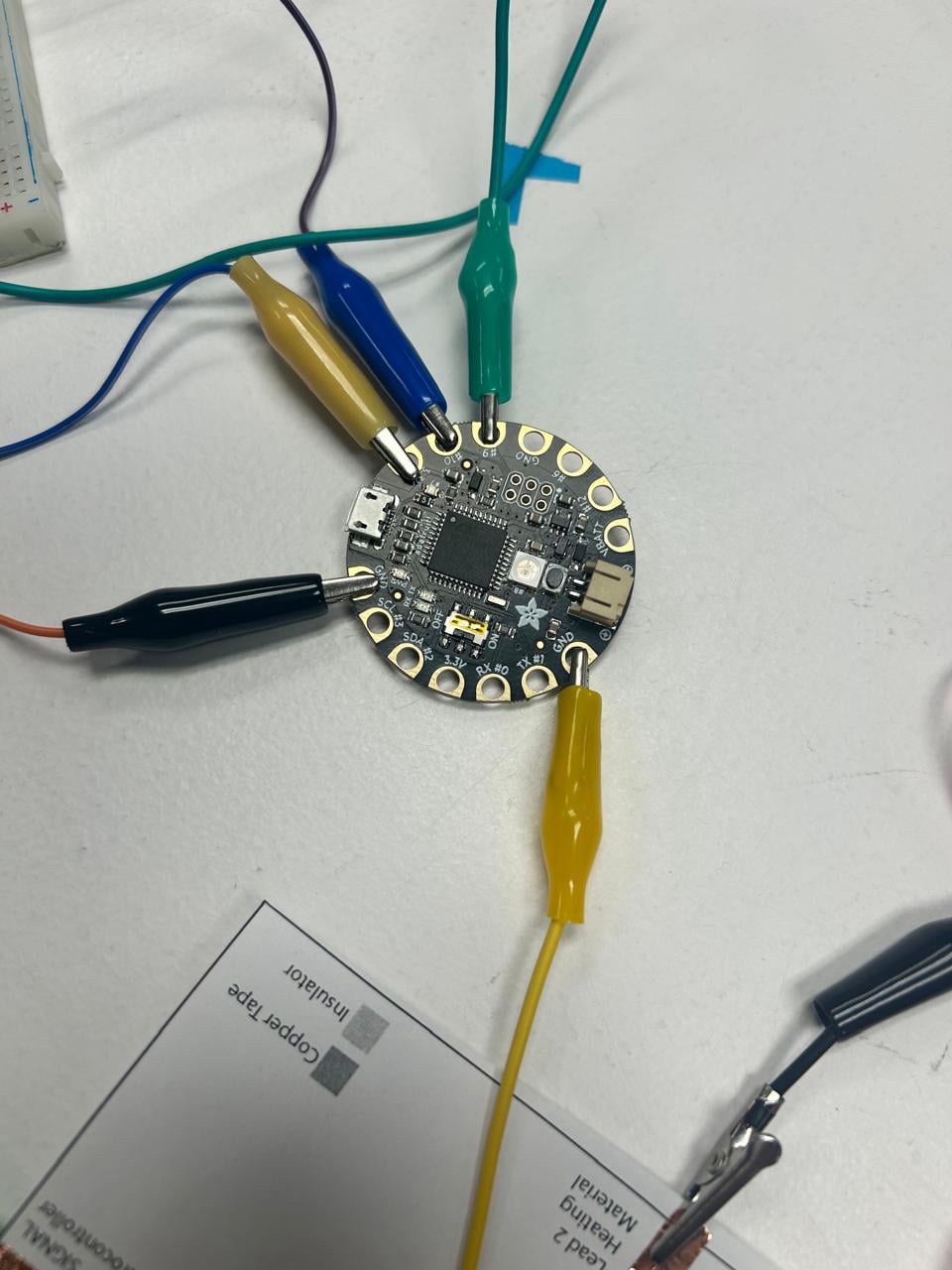

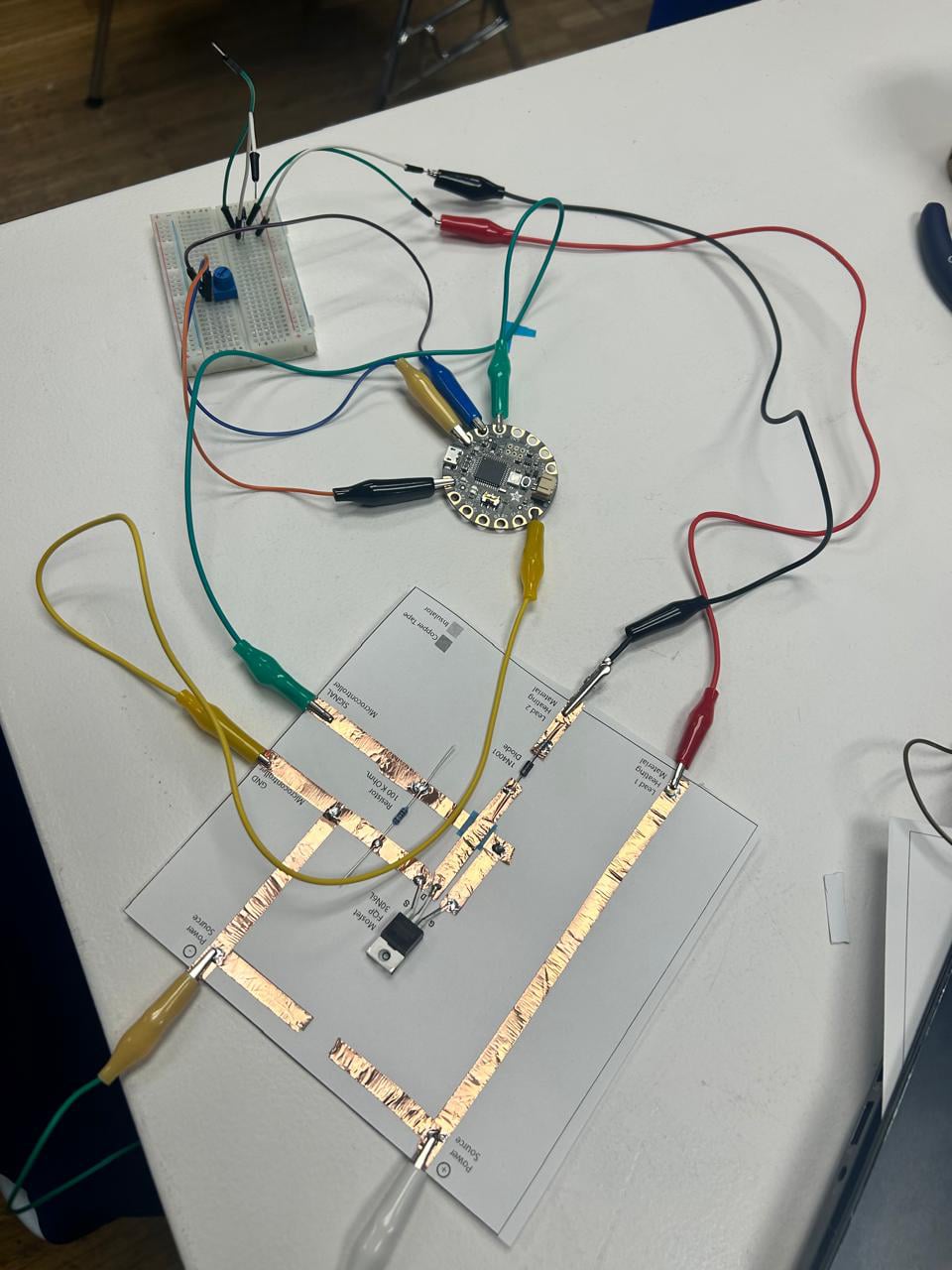

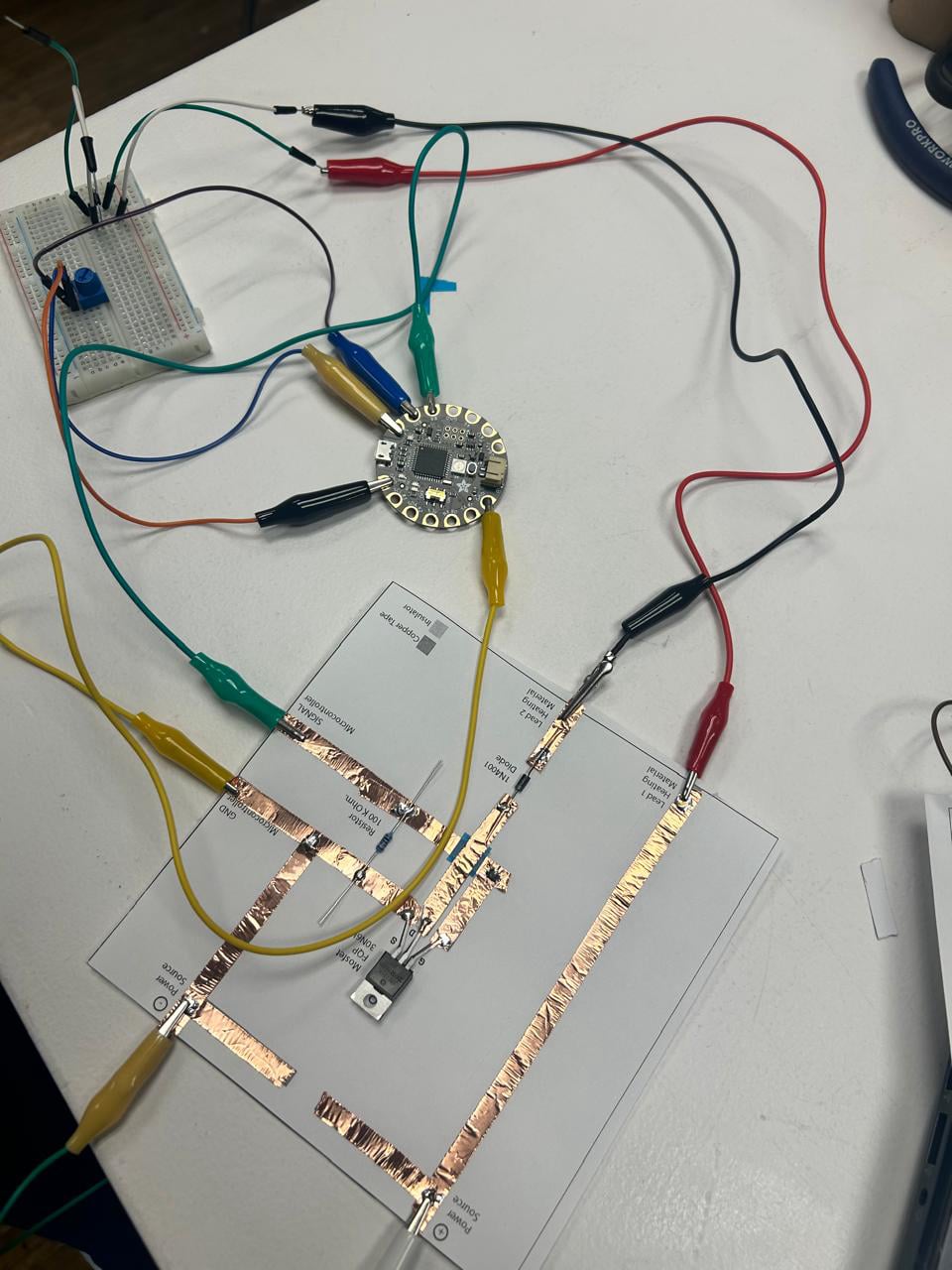

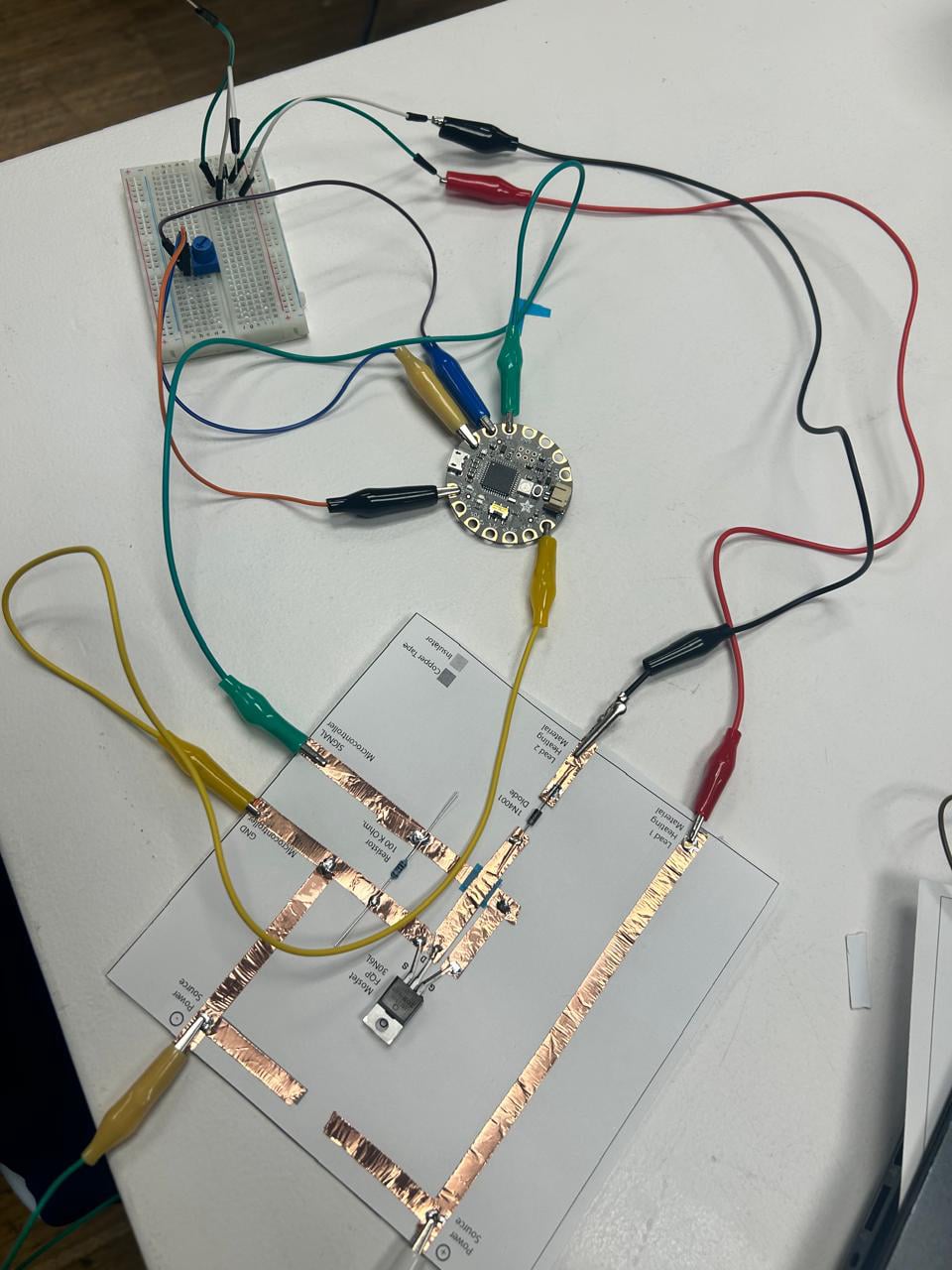

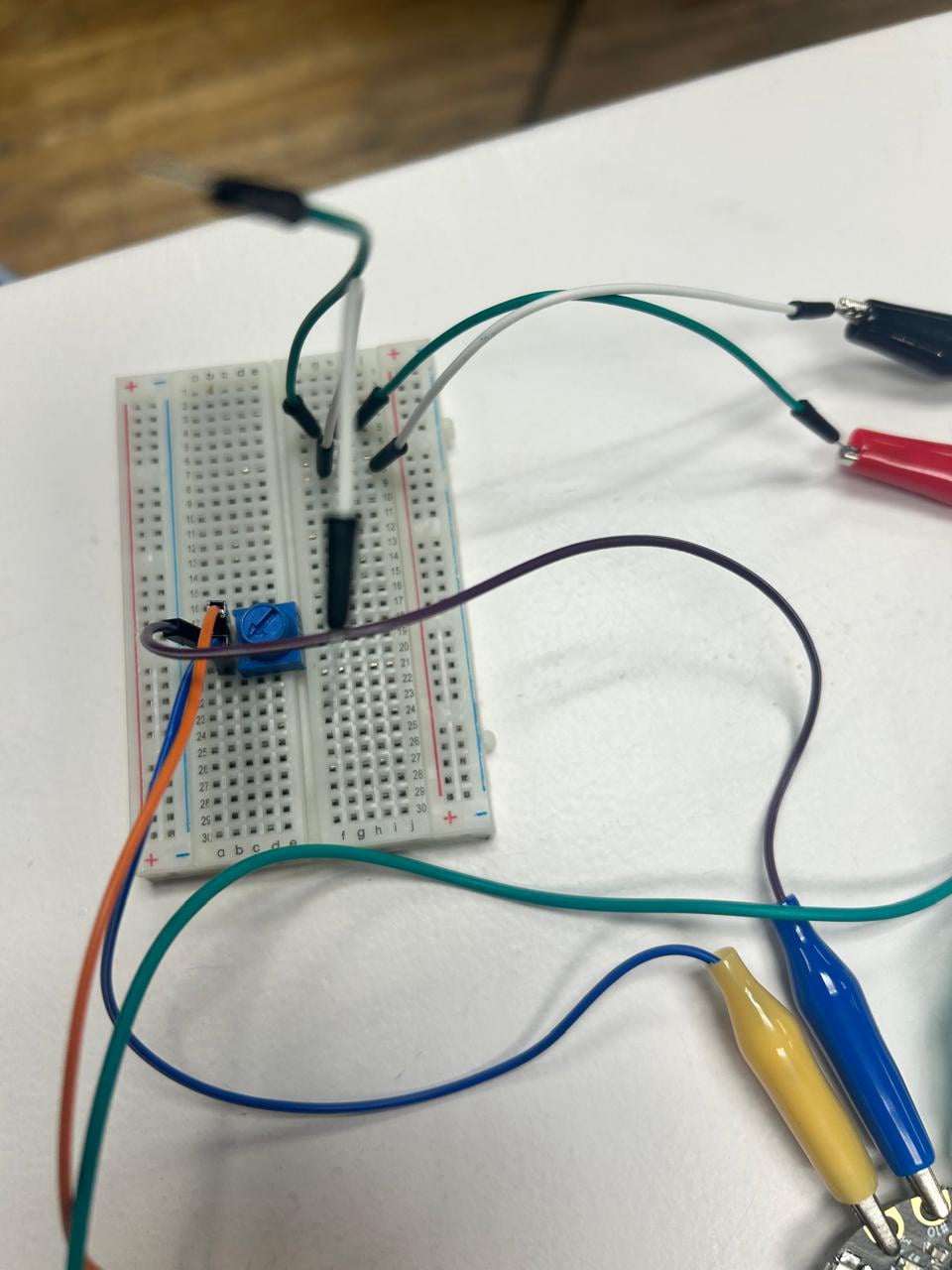

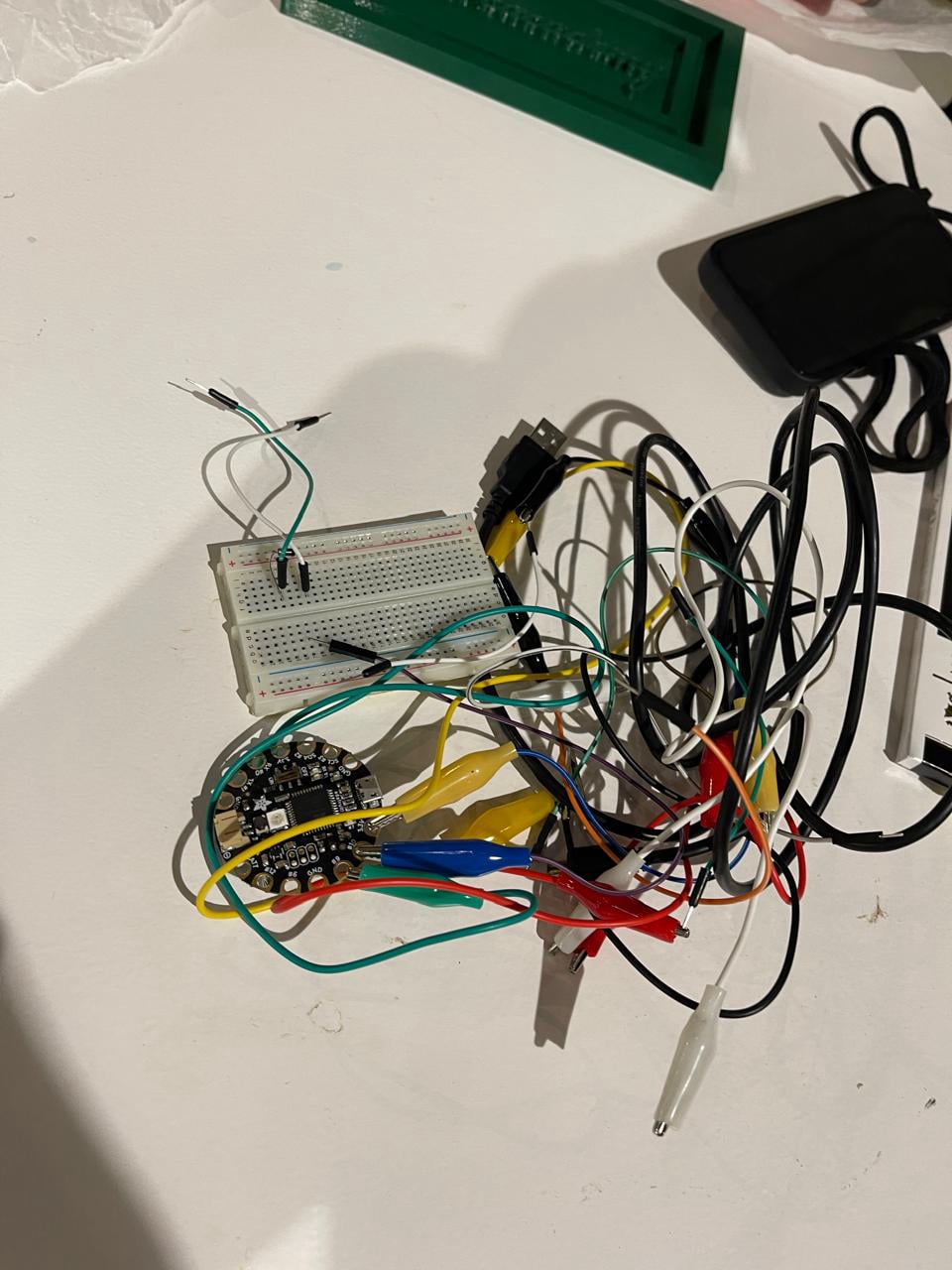

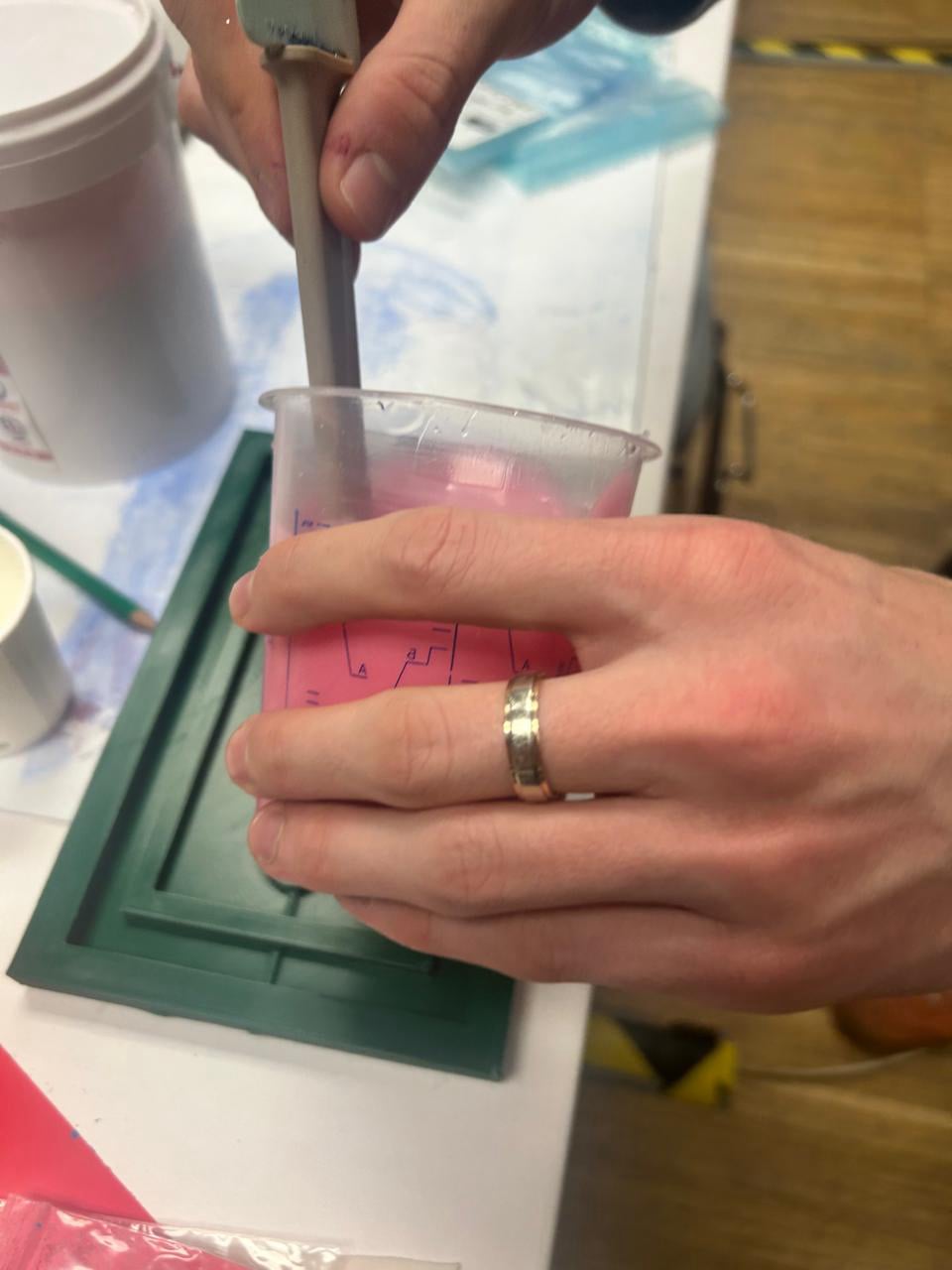

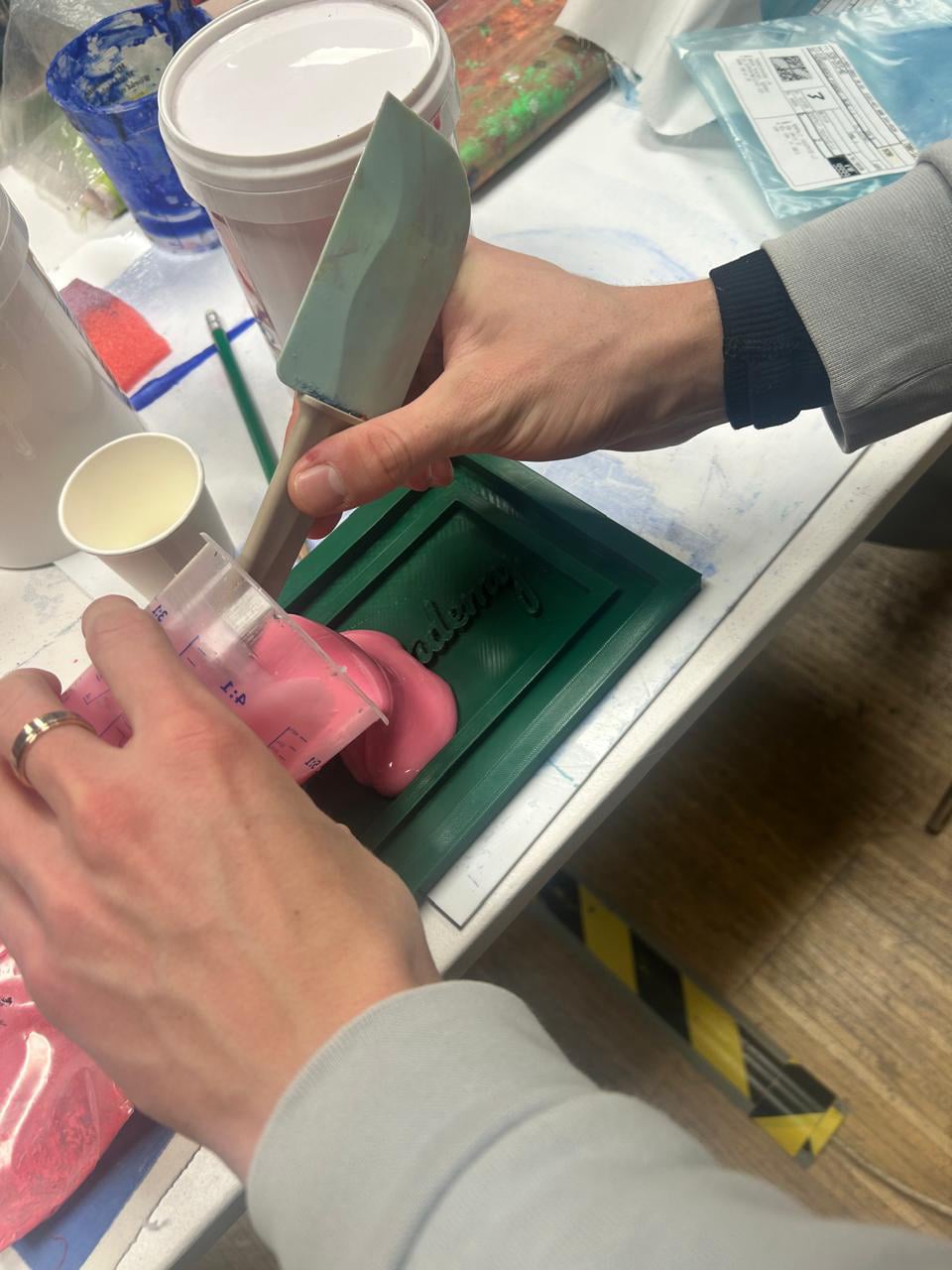

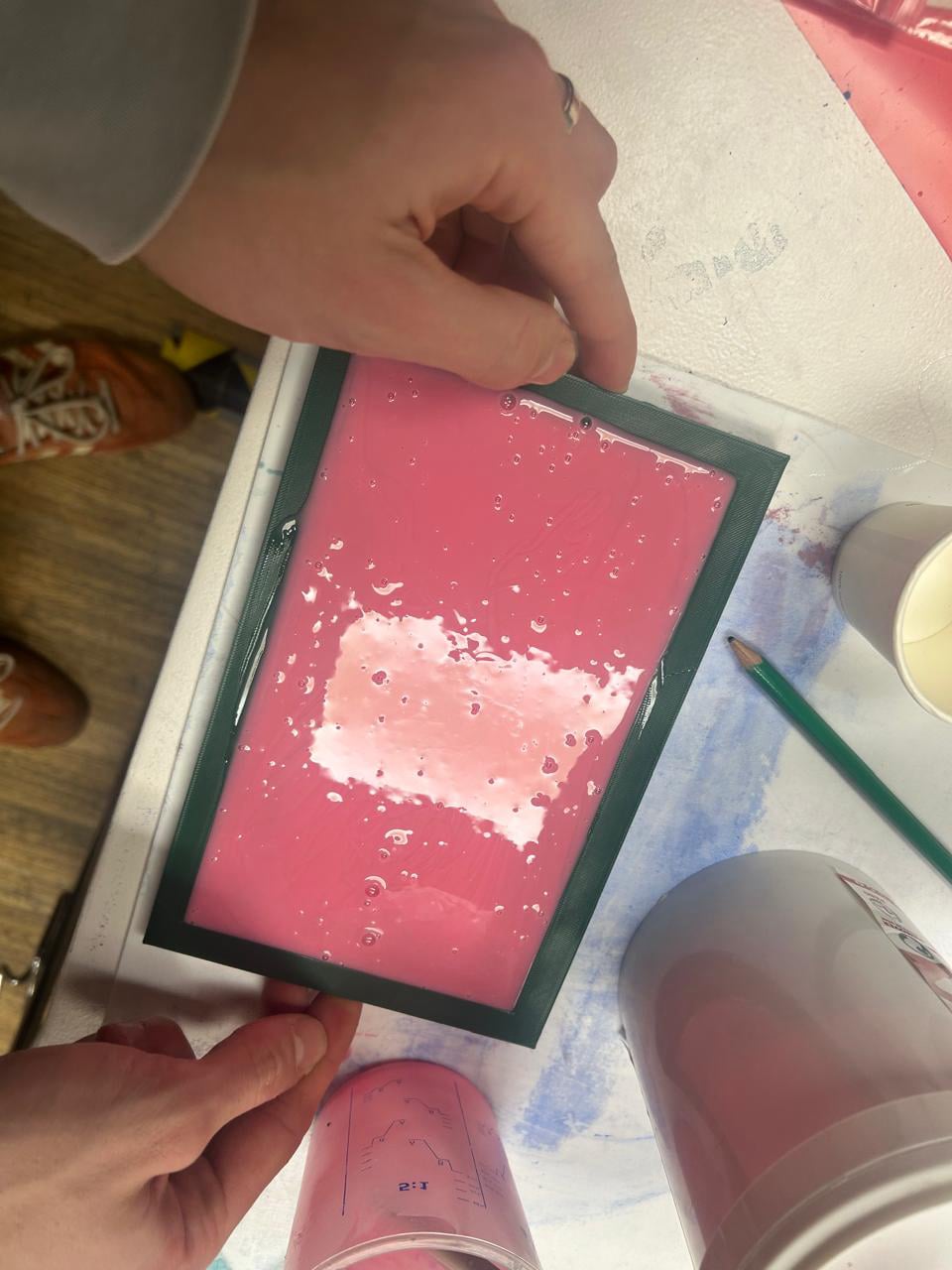

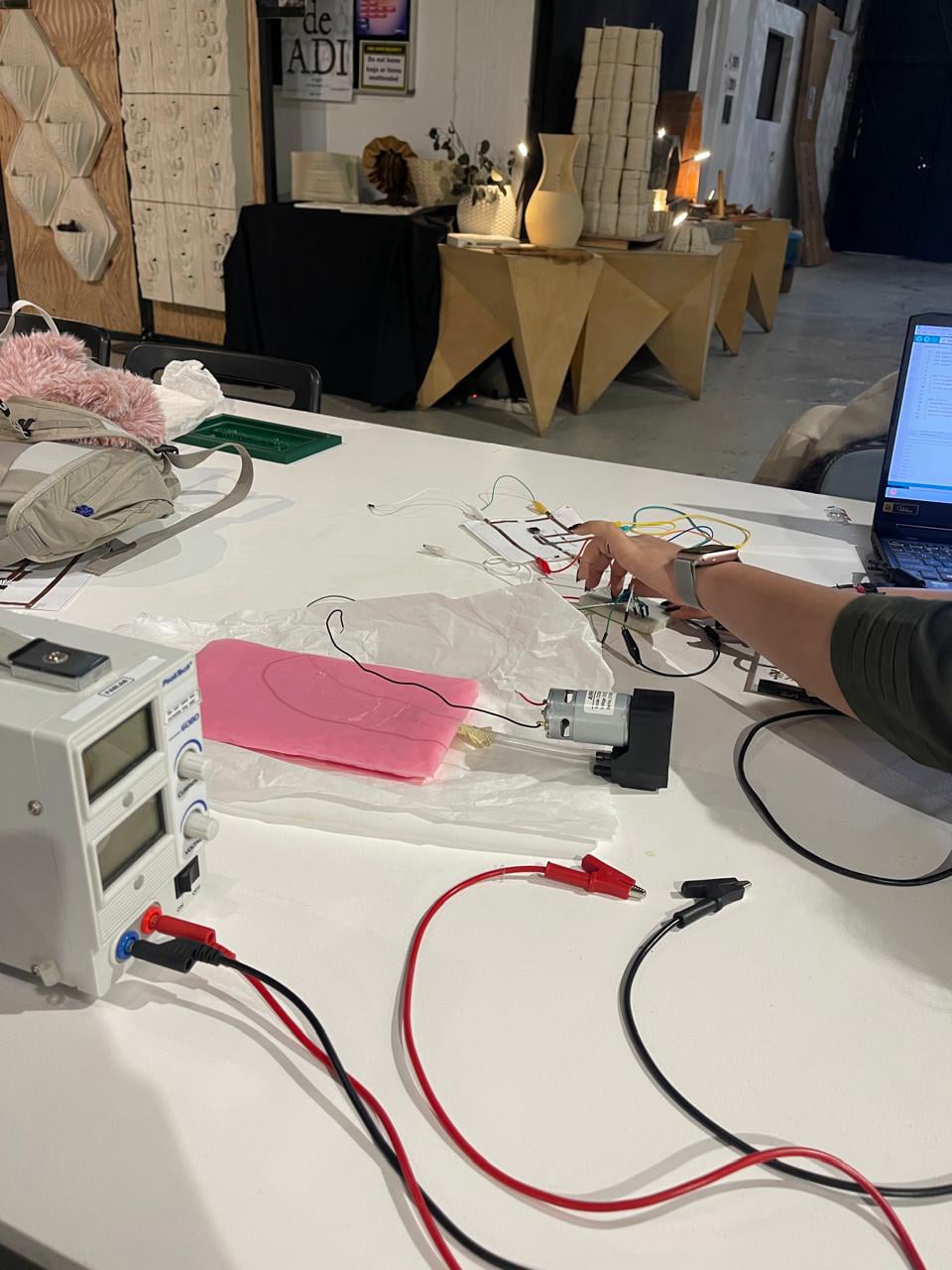

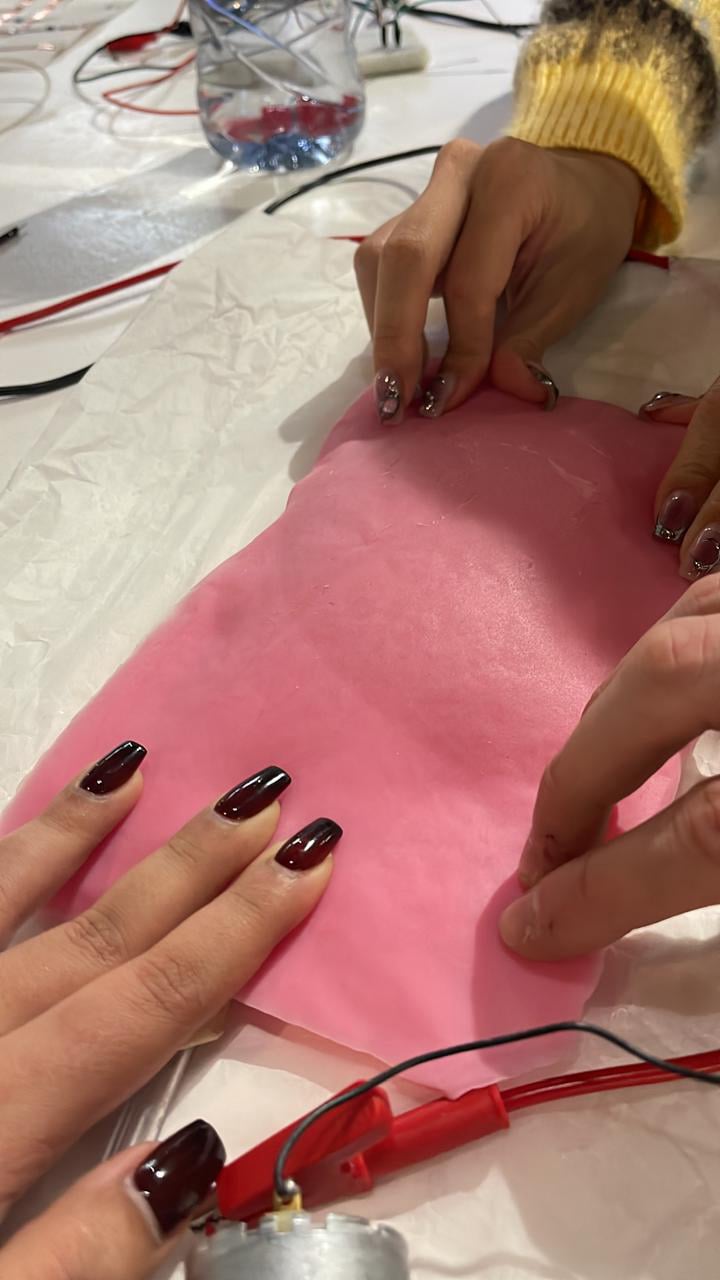

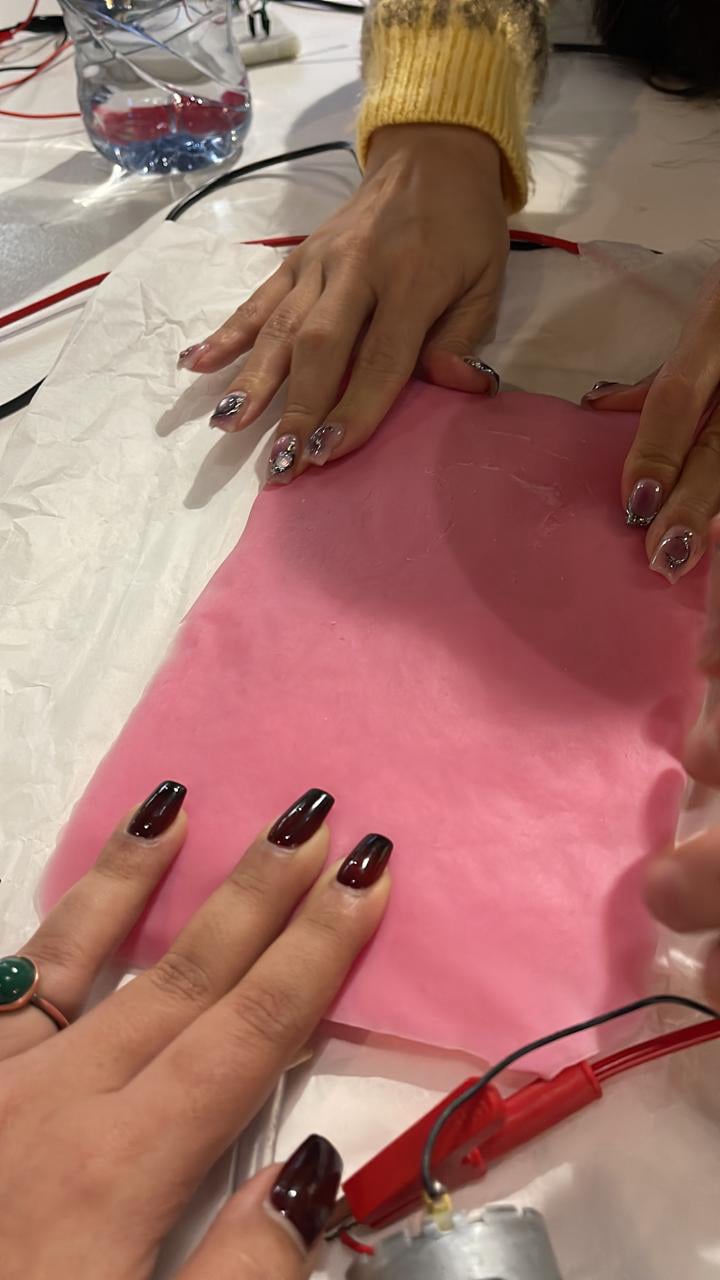

Me, Marius and Dudu decided to work together to create inflatable chocolate. We created a 3D file that said chocacademy and printed that. Once that was printed, we started working on the edible silicon paste and poured that in the mold. We also started working on the arduino component Flora and learned how to connect them to a motor to pump air. Below you can see the images of our exploration.

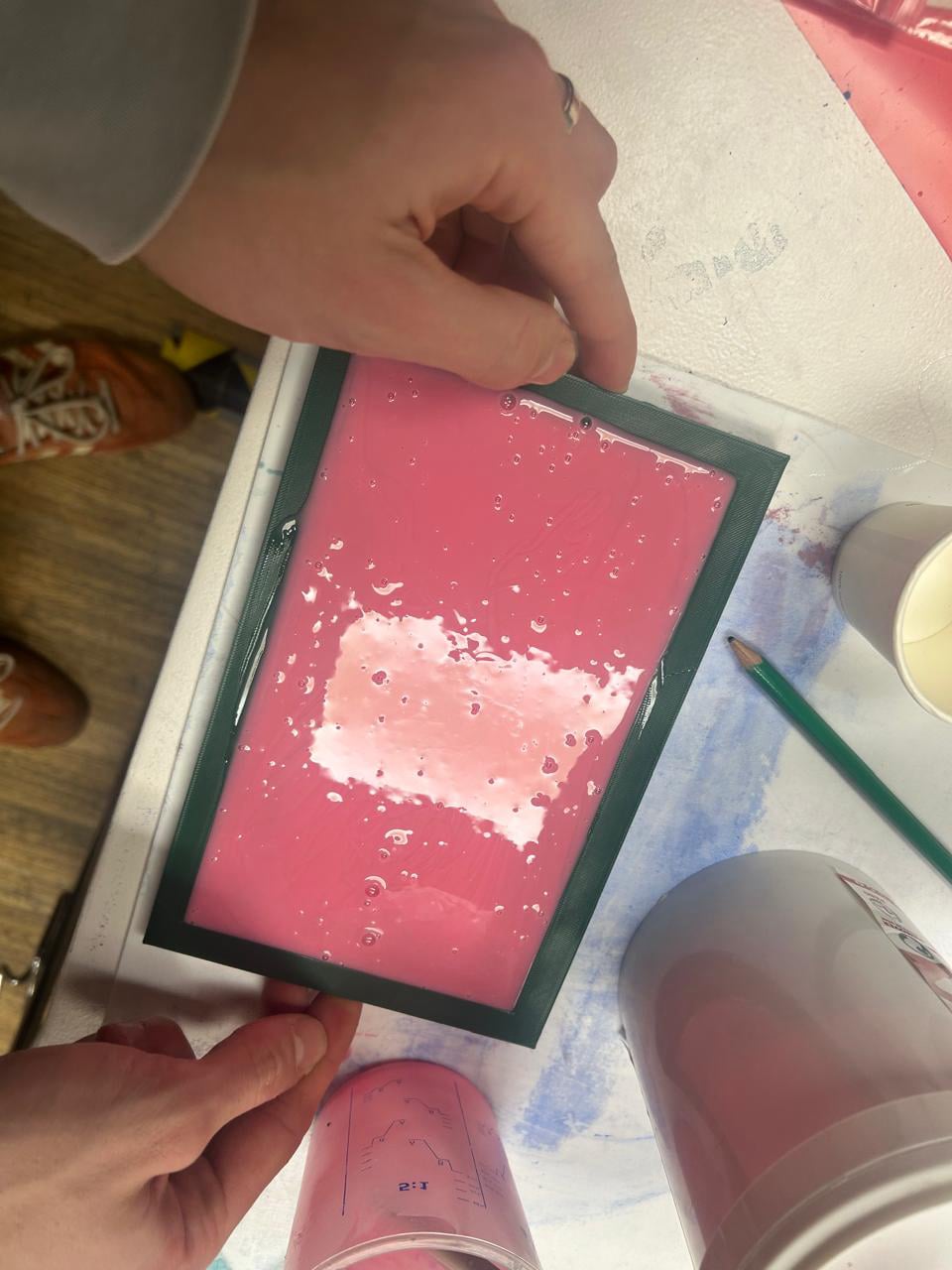

As you can see, we covered all the holes and tried to inflate it but only were able to inflate it very little. We were not able to get the font to inflate and only got a little bubble of air. Our learning was to ensure a closed mold and to make a much thinner cover so to see the inflated part clearly. We were not able to get to the step of melting chocolate and pour it such that the chocacademy font would be cool and funky.

Our next steps would be either to use normal silicon as it is much less porous and would not be as sticky or to use a circular shaped mold as that ensures the inflating process to be equal and perfect.

As part of our experiment, we meticulously sealed all the holes in our mold and attempted to inflate it. Unfortunately, our efforts yielded minimal success—we were only able to achieve a slight inflation, resulting in a small bubble of air. The most significant challenge was our inability to inflate the font section, which remained unresponsive throughout the process.

From this attempt, we learned several important lessons. First, it is crucial to ensure a fully closed mold to prevent any air from escaping. Additionally, the material used for the mold cover needs to be significantly thinner. A thinner cover would not only allow for better inflation but also make it easier to observe the inflated areas clearly.

We were unable to move on to the next planned step of melting chocolate and pouring it into the mold. Our vision was to create a cool and funky design featuring the "Chocacademy" font, but the incomplete inflation prevented us from achieving this.

Looking ahead, our next steps will involve addressing the material and design issues. One option is to switch to regular silicone, as it is less porous and less sticky, which could improve the airtightness of the mold. Another approach would be to experiment with a circular-shaped mold, as this shape provides more uniformity and ensures a smoother, more consistent inflation process.

With these adjustments, we hope to refine our technique and bring the chocolate mold concept to life in a way that matches our creative aspirations.

AI Website Generator