A CNC (Computer Numerical Control) machine is a sophisticated piece of equipment used in manufacturing that utilizes computer programming to control the movement and operation of various machine tools. These machines are capable of performing a wide range of tasks, including cutting, drilling, milling, and turning, with high precision and repeatability.

How a CNC Machine Works

1. Design and Programming:

- CAD (Computer-Aided Design): The process starts with creating a detailed design of the part or product using CAD software.

- CAM (Computer-Aided Manufacturing): The CAD model is then converted into a CAM program, which generates the necessary instructions for the CNC machine, often using G-code, a language used to instruct the machine on how to move and operate.

2. Setup:

- The raw material, or workpiece, is securely fastened to the machine's bed or a holding device like a chuck or vise.

- The appropriate cutting tools are selected and installed.

3. Execution:

- The CNC controller reads the programmed instructions and converts them into electrical signals.

- These signals drive motors and other actuators to move the machine's components (e.g., the spindle, table, or tool holder) precisely as per the programmed coordinates.

- The machine follows the exact path and performs operations like cutting, drilling, or milling to shape the workpiece into the desired form.

4. Monitoring and Feedback:

- Modern CNC machines have sensors and feedback systems that monitor the machining process in real-time.

- Any deviations or errors are automatically corrected to ensure high accuracy.

Importance and Functionality

1. Precision and Accuracy:

- CNC machines can produce parts with extremely tight tolerances and high repeatability, which is crucial in industries where precision is paramount, such as aerospace, automotive, and medical device manufacturing.

2. Efficiency and Productivity:

- Automation reduces the need for manual intervention, allowing CNC machines to operate continuously with minimal supervision. This leads to higher production rates and efficiency.

3. Complexity and Flexibility:

- CNC technology enables the production of complex shapes and intricate designs that would be difficult or impossible to achieve with manual machining.

- The flexibility of CNC machines allows for quick changes in design and production processes, facilitating rapid prototyping and custom manufacturing.

4. Consistency and Quality Control:

- By reducing human error, CNC machining ensures consistent quality across large production runs, maintaining uniformity and adherence to specifications.

5. Cost-effectiveness:

- Despite the initial investment, CNC machines can reduce overall manufacturing costs by lowering labor costs, minimizing waste, and reducing the time required for setup and production.

For this module, we decided to CNC a container for our soil button on which people can step on. It is a simple CNC cut container with simple joineries and a separating compartment to keep the two soils away from each other.

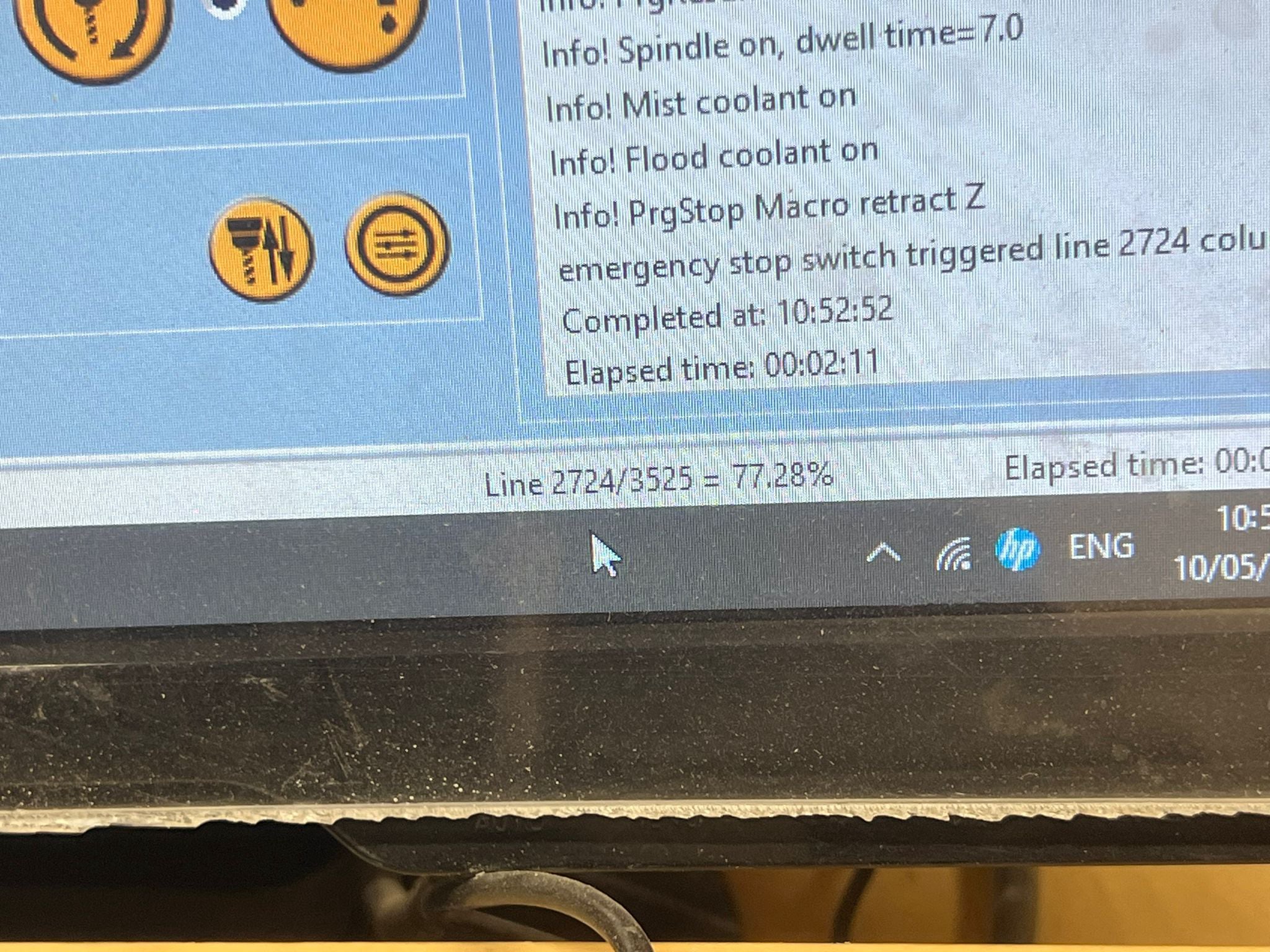

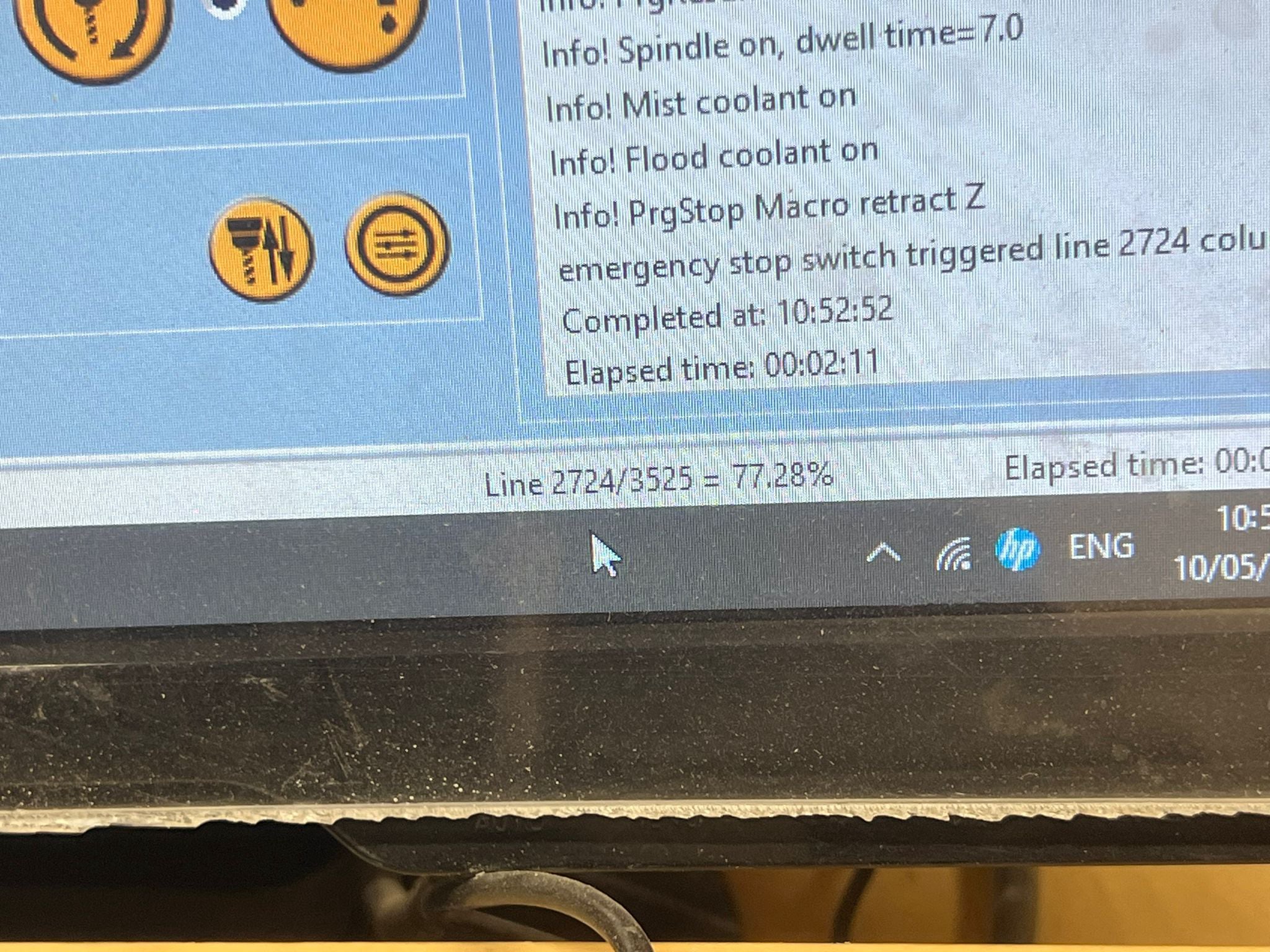

I recently completed a project where I used a CNC machine to create a container for soil. The process was quite intricate and presented several challenges. One of the primary difficulties was creating the model for the container, particularly because the joineries had to be extremely precise to ensure a proper fit and structural integrity. Any deviation could result in parts not aligning correctly, which required meticulous attention to detail during both the design and machining phases.

Using the CNC machine itself was a bit complicated at first. The programming involved was detailed, requiring me to carefully plan each step of the machining process, select the appropriate tools, and set the correct parameters for cutting speeds and feeds. Additionally, setting up the machine and securing the workpiece were crucial steps that demanded precision to avoid any errors during machining.

Despite these challenges, the project was incredibly interesting and rewarding. I learned a great deal about the capabilities and operation of CNC machines, including how to troubleshoot issues that arose and make adjustments on the fly. The experience not only improved my technical skills but also gave me a deeper appreciation for the precision and efficiency that CNC technology can bring to manufacturing. Overall, it was a valuable learning opportunity that enhanced my understanding of both the design and fabrication processes involved in CNC machining.

Website Builder Software