The Beginning

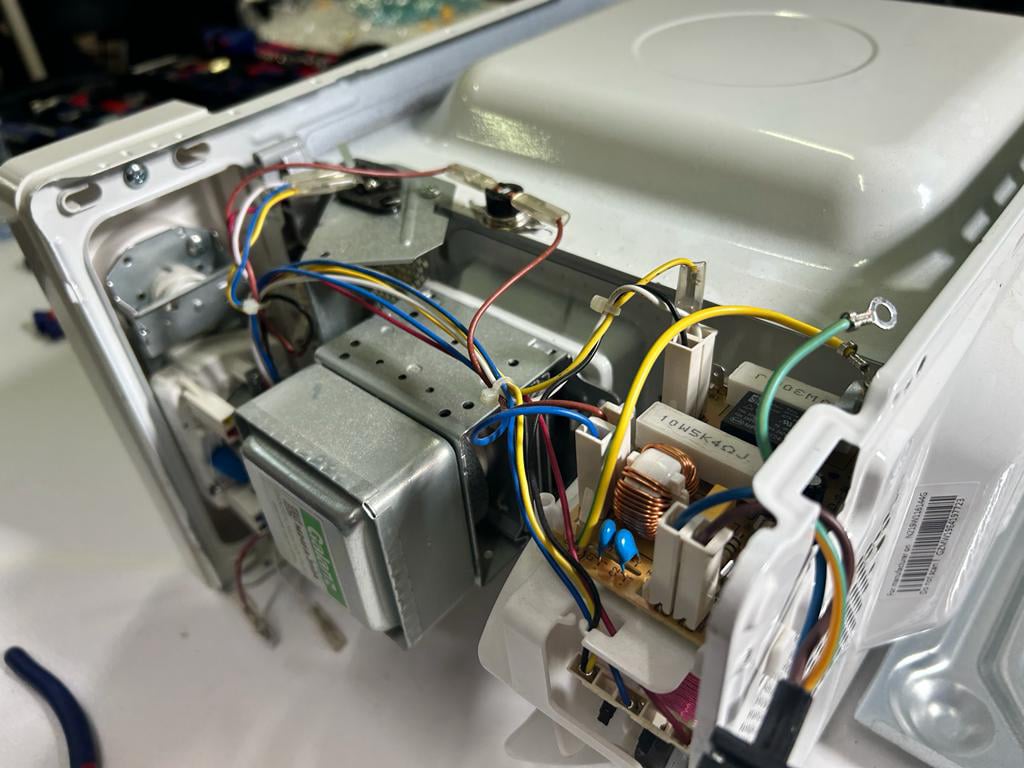

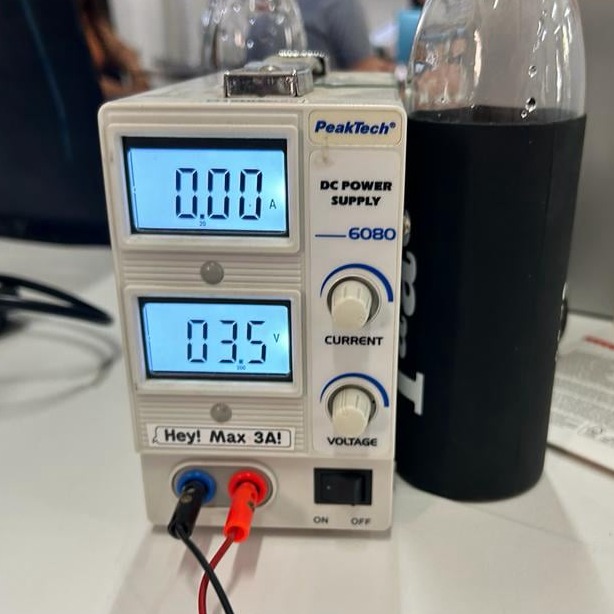

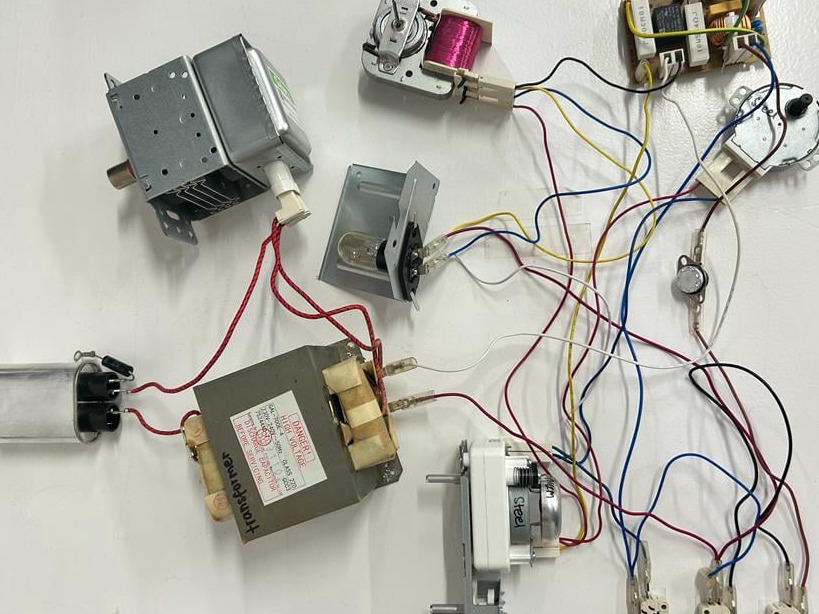

It was an intriguing and educational experience. It provided a hands-on opportunity to gain a deeper understanding of the microwave's internal components and how they work together. The very first step was to disassemble and examine the broken microwave. However, before that, we safely discharged the capacitor to avoid electrical hazards. It emphasized the importance of respecting electrical components and taking precautions when dealing with them.

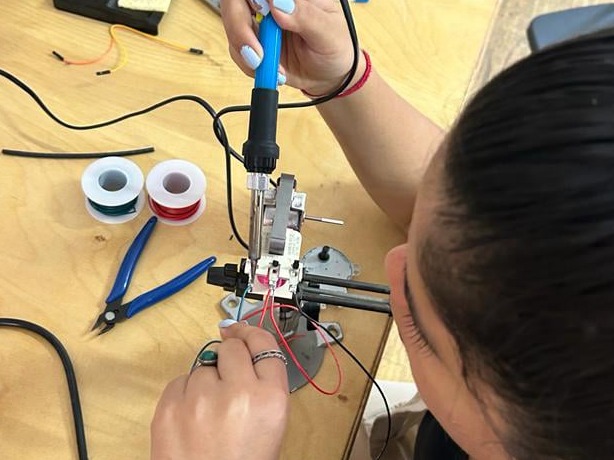

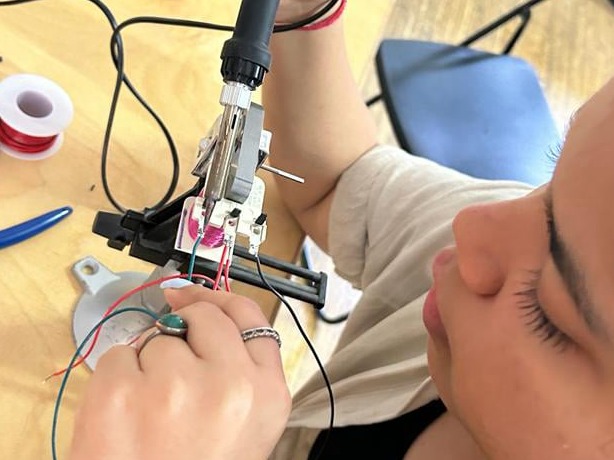

As we disassembled the microwave, we had the chance to identify and label each component. This hands-on approach helped us visually and physically connect theory to practice, enhancing our understanding of the microwave's anatomy. We examined and discussed the functions of key components, such as the transformer, capacitor, magnetron, and motors. This provided insights into how these parts collaborate to generate and control microwave radiation, turntables, and heating.